The profound convergence of industrial automation and artificial intelligence is fundamentally reshaping the landscape of global manufacturing, promising a future where production facilities can anticipate, adapt, and optimize themselves with unprecedented efficiency. At the vanguard of this transformation, a landmark collaboration between industrial giant Siemens and AI powerhouse Nvidia is accelerating the shift from conceptual blueprints to tangible, intelligent factories. This alliance aims to embed AI into every facet of the industrial lifecycle, creating a new operational paradigm where the digital and physical worlds are not just connected but are deeply intertwined in a continuous feedback loop of learning and improvement.

What if a Factory Could Solve 90 Percent of its Operational Problems Before a Single Dollar is Spent on Physical Changes

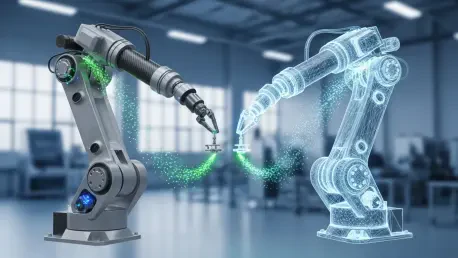

This question, once the domain of science fiction, is rapidly becoming a practical reality. The core of this revolution lies in the evolution of the digital twin, a virtual replica of a physical asset. Through their strategic partnership, Siemens and Nvidia are empowering industries to build photorealistic, physics-based digital twins of entire factories. These are not static 3D models but dynamic, living simulations where AI agents can test millions of operational scenarios—from reconfiguring a production line to adjusting for supply chain variables—all within a risk-free virtual environment.

This capability directly addresses the most pressing challenges of modern industry. In an era demanding faster innovation, greater sustainability, and more resilient supply chains, the ability to validate decisions virtually is a game-changer. By bridging the chasm between digital design and physical deployment, companies can de-risk massive capital investments, shorten development cycles, and unlock efficiencies that were previously unattainable. The goal is no longer just to simulate production but to create fully autonomous and adaptive environments that optimize themselves in real time.

The Next Industrial Revolution Why AI Driven Manufacturing Matters

The current industrial shift represents a fundamental departure from the digital simulations of the past. Traditional models were largely passive, serving as digital blueprints for visualization and planning. Today, the integration of generative AI and accelerated computing transforms these models into active, intelligent digital twins. They function less like a map and more like a live, interactive brain for the physical factory, capable of learning from real-world data, predicting outcomes, and prescribing actions to improve performance.

This leap forward is critical for confronting modern industrial complexities. Manufacturers face immense pressure to innovate faster while simultaneously building more sustainable and resilient operations. AI-driven manufacturing provides the tools to achieve these seemingly contradictory goals. By enabling continuous virtual optimization, companies can refine processes on the fly, identify potential bottlenecks before they occur, and design supply chains that can withstand unforeseen disruptions, all while minimizing waste and energy consumption.

The ultimate vision is the creation of a seamless loop between the digital and physical realms, leading to fully autonomous production environments. In such a system, the intelligent digital twin continuously receives data from its physical counterpart, runs simulations to find better ways of operating, and then implements those improvements in the real world with minimal human intervention. This symbiotic relationship paves the way for a new era of hyper-efficient, self-adapting, and resilient manufacturing.

A Strategic Alliance Forging the Future of Production

Central to this movement is the shared vision of Siemens and Nvidia to create what they term an “Industrial AI Operating System.” This comprehensive platform is designed to establish a new paradigm for manufacturing, leveraging AI to enhance every stage from design and engineering to operations and service. Their collaboration is already making its mark, with the Siemens Electronics Factory in Erlangen, Germany, undergoing a transformation this year to become one of the first fully AI-driven adaptive manufacturing sites.

This partnership is built on a foundation of complementary strengths. Nvidia provides the core AI infrastructure, including its advanced simulation libraries, foundational models like NIM and Nemotron, and powerful computing frameworks. This forms the technological bedrock for building and running complex industrial simulations at scale. In turn, Siemens contributes its profound industrial domain expertise, a dedicated team of hundreds of AI specialists, and its extensive portfolio of industrial hardware and software, including the Siemens Xcelerator platform.

The joint efforts are concentrated on several high-impact zones poised for disruption. These include the development of AI-native Electronic Design Automation (EDA) to accelerate semiconductor innovation, the creation of sophisticated AI-powered simulation and virtual testing environments, and the deployment of AI-driven systems for adaptive manufacturing and supply chain management. Together, these initiatives form a holistic approach to building the intelligent “AI-factories” of the future.

The Visionary Perspective Redefining the Digital Twin

Nvidia CEO and Founder Jensen Huang has characterized this moment as a “new industrial revolution,” one fueled by the potent combination of generative AI and accelerated computing. He emphasizes that this alliance elevates the digital twin from a static model into the “active intelligence of the physical world.” This perspective reframes the technology not merely as a tool for visualization but as a platform for simulating incredibly complex systems in software, which can then be automated and operated seamlessly in physical reality.

This evolution from a passive simulation to an interactive intelligence is what gives the new generation of digital twins their transformative power. They are no longer just a reflection of the physical asset but an integral part of its operational brain. By processing real-time data and running predictive models, the digital twin can guide its physical counterpart, enabling industries to achieve a level of optimization and autonomy that was previously unimaginable.

A concrete example of this integration is Siemens’ plan to embed Nvidia NIM and Nemotron open AI models directly into its EDA software suite. This strategic move is set to advance generative and agentic workflows for designing complex semiconductors and Printed Circuit Boards (PCBs). By specializing these models with domain-specific knowledge, Siemens aims to maximize design accuracy while lowering operational costs by deploying the most efficient AI model for each specific engineering task.

The Industrial Metaverse From Concept to Commercial Reality

The flagship technology bringing this vision to life is the Digital Twin Composer, a platform now available on the Siemens Xcelerator Marketplace. It serves as the primary engine for realizing the Industrial Metaverse, moving far beyond simple visualization. The Composer integrates Siemens’ robust digital twin technology with the high-fidelity simulation capabilities of Nvidia Omniverse libraries and a constant flow of real-time engineering data from the factory floor.

This powerful synthesis empowers companies to create photorealistic, physics-based virtual 3D models of any product, process, or entire factory. Users can then place this digital twin within a virtual scene and simulate its operation over time, precisely visualizing the effects of countless variables, from engineering changes to shifting weather patterns. With Siemens’ software serving as the central data backbone, the Digital Twin Composer provides a powerful virtual sandbox for applying industrial AI and simulation to make better, faster decisions.

The transformative impact of this technology is already being demonstrated in a collaboration with PepsiCo. The consumer goods giant is converting its U.S. manufacturing and warehouse facilities into high-fidelity 3D digital twins. Within this virtual environment, AI agents simulate and refine countless system changes, allowing teams to identify up to 90% of potential operational issues before any physical capital is deployed. The results have been striking: an initial deployment produced a 20% increase in throughput, accelerated design cycles, and reduced capital expenditures by 10-15% by uncovering hidden capacity.

Expanding the Ecosystem AI Across the Industrial Value Chain

Siemens’ strategy extends well beyond its pivotal partnership with Nvidia. The company is also collaborating with Microsoft to develop and deploy industrial copilots, AI assistants designed to enhance productivity and innovation for workers across the industrial spectrum. These tools are being embedded throughout the value chain, from initial design and simulation to product lifecycle management and factory operations.

To make these advanced capabilities accessible, Siemens is launching nine new AI-powered copilots for its core software offerings, including Teamcenter, Polarion, and Opcenter, via the Siemens Xcelerator Marketplace. This move democratizes access to sophisticated AI assistance, enabling companies of all sizes to leverage its benefits. The impact of this expanding AI ecosystem is evident across a diverse range of industries, from accelerating drug discovery in life sciences by up to 50% to pioneering clean fusion energy and speeding up the development of software-defined vehicles in the automotive sector. Even consumer technology is being integrated, with a collaboration with Meta set to bring Industrial AI to Meta Ray-Ban AI Glasses, providing factory workers with hands-free, real-time guidance.

The strategic alignment of Siemens with key technology partners established a clear and actionable roadmap for the future of manufacturing. By integrating deep industrial expertise with cutting-edge AI infrastructure, these collaborations moved the concept of the smart factory from a theoretical ideal to a commercial reality. The successful deployments across multiple sectors demonstrated that the fusion of digital intelligence and physical production yielded tangible gains in efficiency, resilience, and sustainability, marking a definitive step into a new industrial era.