The advent of advanced space technologies continues to redefine our understanding of space travel and its logistics. Among these innovations is SpaceCAL, a revolutionary 3D printer designed by engineers at UC Berkeley, which promises to transform how we approach long-duration space missions. This cutting-edge technology not only aims to improve the efficiency of space exploration but also stands to significantly enhance medical care in space. From addressing logistical challenges to enhancing astronaut safety with on-demand medical supplies, SpaceCAL’s capabilities represent a significant leap forward in space technology.

Innovation in Space Technology

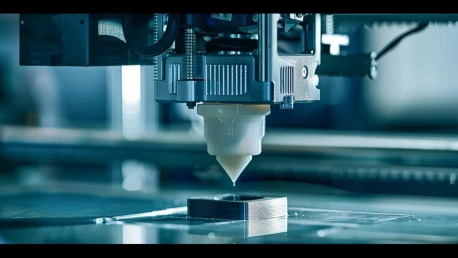

SpaceCAL is a remarkable achievement in the realm of space technology, developed explicitly to assist astronauts during extended missions to the Moon, Mars, and beyond. Engineers at UC Berkeley have devised this 3D printer to address the logistical challenges associated with carrying extensive spare parts and tools. SpaceCAL’s primary objective is to enable on-demand fabrication of essential components, thereby reducing mission costs and increasing self-sufficiency. Traditional methods necessitate carrying a multitude of spare parts, which adds significant weight and complexity to missions. SpaceCAL eliminates this need by allowing astronauts to create necessary parts as and when required, using a special liquid plastic. This level of innovation paves the way for more efficient and practical long-term exploration.The concept of space-based manufacturing is not new, but SpaceCAL brings an unprecedented level of sophistication to the table. By removing the necessity of transporting countless spare parts and tools, this technology significantly lightens the load and reduces the footprint of space missions. Furthermore, the on-demand production capability means that astronauts can respond to unexpected repairs and needs, making missions more adaptable and resilient. This leap in technology signifies a shift towards more autonomous and self-sustaining missions, which are crucial for exploring distant planets and establishing sustainable human presence on extraterrestrial surfaces.

Suborbital Testing and Success

In June 2024, SpaceCAL underwent a critical testing phase aboard Virgin Galactic’s VSS Unity during mission 07. This suborbital flight marked a significant milestone, allowing the 3D printer to operate in actual space conditions. During the mission, SpaceCAL was subjected to 140 seconds of microgravity to demonstrate its printing capabilities. The suborbital test was a resounding success, with SpaceCAL autonomously printing objects, including a toy shuttle, using an innovative liquid plastic. This test provided invaluable insights into how the printer functions in microgravity, validating its utility for future space missions. The successful suborbital flight reassures that SpaceCAL can reliably perform its tasks when deployed on longer-duration missions.The microgravity environment of space presents unique challenges for manufacturing processes, but SpaceCAL overcame these hurdles with ease. By successfully demonstrating its ability to print objects autonomously in such conditions, SpaceCAL has proven to be a reliable tool for future space explorations. This successful trial is a crucial step towards integrating 3D printing technologies into the everyday operations of space missions. The insights gained from this test not only confirm SpaceCAL’s effectiveness but also help refine its design for even better performance in future missions.

Advanced Printing Technique

Central to SpaceCAL’s success is its use of an advanced additive manufacturing technique known as Computed Axial Lithography (CAL). Developed by Berkeley engineers in 2017, CAL sets itself apart from traditional 3D printing methods by using light to rapidly produce complex, solid shapes from a viscous liquid. This technique greatly enhances the speed and efficiency of printing, enabling the creation of parts in just 20 seconds. SpaceCAL’s superior speed and efficiency make it a game-changer for space missions. The CAL method allows for the production of intricate components that would otherwise be challenging or impossible to create using conventional 3D printing techniques. By leveraging light and liquid plastic, SpaceCAL achieves a level of precision and detail that is crucial for the diverse needs of space exploration.This breakthrough technology not only shortens production times but also expands the range of possible applications, making SpaceCAL a versatile tool in space missions. The ability to rapidly produce complex shapes and objects on demand is particularly beneficial in a space environment where time and resources are often limited. The efficiency of the CAL method could be pivotal in minimizing downtime during missions, ensuring that astronauts can quickly address any technical issues that arise. Additionally, the high level of precision offered by CAL means that the parts produced are reliable and fit for purpose, which is essential in the rigorous conditions of space.

Versatile Applications

SpaceCAL’s potential extends far beyond the manufacturing of spare parts. On Earth, the printer can produce over 60 different materials, including silicones, glass composites, and biomaterials. This versatility suggests a myriad of applications, from spacecraft repair to addressing medical emergencies in space. For instance, SpaceCAL could potentially print dental crowns or skin grafts, addressing immediate medical needs that might arise during long space missions. The ability to rapidly produce medical supplies on-demand significantly enhances the quality of life and safety for astronauts. This versatility makes SpaceCAL an invaluable tool not just for technical repairs but also for maintaining astronaut health and well-being.The broad spectrum of materials that can be used in SpaceCAL expands its utility, making it a multi-functional tool in the space arsenal. The capacity to produce medical supplies directly onboard spacecraft or space stations can be a game-changer for long-duration missions where medical emergencies are a significant concern. By offering on-demand solutions for both technical and medical needs, SpaceCAL stands to streamline operations and reduce the risks associated with carrying limited supplies. Furthermore, its ability to produce a wide range of materials means that it can adapt to various unforeseen circumstances, enhancing the mission’s overall flexibility and preparedness.

Support and Collaboration with NASA

NASA has been a crucial collaborator in the development of SpaceCAL, providing $1.4 million in grant funding and engineering assistance. This partnership underscores the strategic importance of the 3D printer for future space missions. NASA’s investment in and endorsement of SpaceCAL highlight the agency’s commitment to leveraging advanced manufacturing techniques to enhance mission reliability and efficiency. NASA’s support demonstrates the broader implications of SpaceCAL’s success. The ability to print essential components and medical supplies on-demand reduces the overall mission weight and cost, making space travel more feasible and sustainable. NASA’s collaboration with UC Berkeley not only fosters innovation but also ensures that the technology meets the rigorous standards required for space missions.The backing of a reputable and influential organization like NASA adds significant credibility to the SpaceCAL project. It also ensures that the technology developed is aligned with the practical needs and challenges of space exploration. This collaboration is a testament to the importance of interdisciplinary partnerships in advancing space technology and underscores the potential for SpaceCAL to become a standard tool in the arsenal of space explorers. NASA’s involvement ensures that the development of SpaceCAL is grounded in practical realities and prepared to meet the exacting demands of space missions, pushing the boundaries of what is possible in space exploration.

Efficiency in Microgravity

One of the most intriguing findings from SpaceCAL’s tests is the discovery that certain parts can be manufactured more efficiently in space than on Earth. This revelation is crucial, as it reaffirms the viability of in-situ manufacturing, which is essential for the long-term sustainability of space missions. The reduced need to carry a large inventory of spare parts and tools could significantly lower the costs and weight of space missions. Moreover, SpaceCAL’s autonomous operation means that astronauts can focus on other critical tasks, enhancing overall mission efficiency. This new approach to manufacturing in space opens up possibilities for more practical and extended exploration missions.The revelation that microgravity can enhance manufacturing efficiency introduces a new avenue for space exploration logistics. The potential to produce high-quality parts faster and more effectively in space can revolutionize how missions are planned and executed. By capitalizing on the unique conditions of space, SpaceCAL offers a resource-efficient solution that aligns with the sustainability goals of modern space exploration. The ability to autonomously produce necessary components also reduces the burden on astronauts, allowing them to concentrate on mission-critical activities. This advancement is a significant step towards achieving the goal of longer, more sustainable human presence in space.

Future Prospects

The rise of advanced space technologies continues to reshape our comprehension of space travel and its logistics. One such groundbreaking innovation is SpaceCAL, a state-of-the-art 3D printer developed by engineers at UC Berkeley. This revolutionary device has the potential to fundamentally alter the way we conduct long-duration space missions. By enabling the on-site manufacturing of essential components and supplies, SpaceCAL aims to vastly improve the efficiency of space exploration. Furthermore, it holds the promise of significantly advancing medical care for astronauts. In the harsh and isolated environment of space, medical supplies and equipment are often hard to come by, making on-demand production critical. SpaceCAL addresses these logistical hurdles by allowing astronauts to produce necessary medical tools and supplies directly onboard, thereby bolstering their safety and well-being. This innovative technology represents a monumental leap forward, not only in space exploration but also in ensuring that astronauts can carry out missions with enhanced safety and support.