The establishment of Trumpf’s new Smart Factory in Farmington, Connecticut, reflects a pivotal moment in the trajectory of U.S. manufacturing. With the continuous evolution of global industry demands, Trumpf’s strategic investment underscores a commitment to enhancing manufacturing processes through automation and connectivity. This facility is not just about increasing production; it represents a shift towards the future of manufacturing, focusing on adaptability and data-informed approaches. As one of the leading figures in laser technology and metal fabricating machine tools, Trumpf’s move seeks to bolster local manufacturing capabilities while showcasing cutting-edge technologies.

A Legacy of Excellence and Innovation

Expansion and Technological Prowess

Since establishing its roots in Connecticut in 1969, Trumpf Inc. has increasingly fortified its position within the American manufacturing landscape. The new Smart Factory is a testament to this enduring legacy, representing an evolution from traditional manufacturing into the realm of smart, automated processes. With an investment of $40 million, the facility is strategically aligned with Trumpf’s “local-for-local” initiative, aspiring to meet local production needs while remaining sensitive to the challenges faced by the industry. By broadening its production capabilities, this new Factory amplifies Trumpf’s ability to generate thousands of unique parts for a multitude of advanced machines utilized in various prominent sectors such as automotive, aerospace, and even agriculture.

The Smart Factory is not merely about enhanced production; it serves as a practical demonstration hub where manufacturers can interact with and understand the potential of automated systems. This interaction is crucial as it tackles widespread industry complications such as reshoring production and addressing the skilled labor shortage, fostering a safer and more competitive environment. Furthermore, Trumpf’s commitment to fostering a trend towards decentralized and agile manufacturing setups is reflected in its efforts to create over 300 Smart Factories throughout North America. This proactive stance is indicative of a movement aimed at not only efficiency but also sustainability, reflecting Trumpf’s forward-thinking vision for manufacturing.

Commitment to Local Markets

Trumpf’s consistent expansion and investment within the U.S., particularly in Connecticut, underline its commitment to local markets. The Farmington facility enhances the company’s capacity to accommodate a variety of industries, reinforcing Trumpf’s strategy to remain an integral part of the American manufacturing sector. This strategic focus on addressing specific regional demands allows Trumpf to provide customized solutions, ensuring responsiveness to local needs while integrating the latest technologies. As such, Trumpf’s efforts are not only about improving their operational framework but also about serving as a model for modern manufacturing practices, setting new standards for the industry.

Moreover, the expansion illustrates Trumpf’s dedication to bolstering local employment and economic growth. The introduction of a new press brake production line in the foreseeable future is just one such example. Set to commence operations in 2026, this initiative is anticipated to generate additional job opportunities, further anchoring Trumpf’s position within the regional economic fabric. By aligning production capabilities with employment generation, Trumpf is positioned to make significant contributions, not only to its own growth but also to the broader economic landscape of the region.

Addressing Workforce Challenges

Advancing Skilled Workforce Training

Recognizing the significance of a well-trained workforce, Trumpf is taking pivotal steps toward enhancing education and skills among industry professionals. One of the core facets of this initiative is the expansion of the Trumpf Training Center in Farmington, which is now equipped with the latest systems and realistic setup scenarios. This state-of-the-art facility is designed to prepare the next generation of technicians and operators, equipping them with the necessary skills to thrive in a technologically advanced manufacturing environment. By focusing on hands-on training and immersive learning experiences, Trumpf aims to bridge the gap between educational offerings and industry demands, nurturing a skilled workforce that can adeptly navigate the complexities of modern manufacturing.

In addition to expanding its training facilities, Trumpf is pioneering an apprenticeship consortium in collaboration with other Connecticut manufacturers. This collaboration, supported by organizations like AdvanceCT and the German-American Chamber of Commerce, aims to leverage Trumpf’s expertise in apprenticeship programs to elevate workforce skills across the region. The emphasis is on developing a curriculum that is in tune with contemporary industry needs, ensuring that apprentices receive comprehensive training that aligns with the latest technological advancements. By championing these initiatives, Trumpf is playing an instrumental role in fostering a robust and capable workforce, well-equipped to meet the evolving challenges of the manufacturing sector.

Strategic Partnerships and Community Engagement

The efforts to enhance workforce skills extend beyond training facilities to active partnerships with local institutions and industry players. Such collaborations are crucial in creating a cohesive approach to workforce development, where knowledge transfer and resource sharing become pivotal elements. Through strategic partnerships, Trumpf not only enhances its training programs but also contributes to the broader community by fostering economic development and supporting regional industries. These collaborations are instrumental in creating a network of skilled professionals capable of driving innovation and meeting the complex demands of modern manufacturing.

Connecticut Governor Ned Lamont acknowledged Trumpf’s initiatives during the grand opening of the new factory, emphasizing how such efforts position the state as a hub of innovation and manufacturing excellence. With a contribution of $2.5 million from Connecticut’s Strategic Supply Chain Initiative, the state’s endorsement further solidifies the significance of Trumpf in advancing economic growth and maintaining a competitive edge in the global market. By intertwining education, technology, and community engagement, Trumpf’s initiatives offer a blueprint for sustainable development and underscore the strategic importance of investing in human capital to ensure long-term prosperity in the manufacturing sector.

Pioneering Future Manufacturing Trends

Integrating Automation and Connectivity

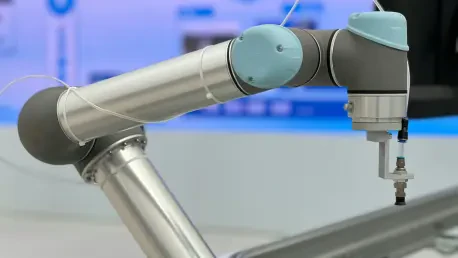

The Farmington Smart Factory stands as a beacon for the future of manufacturing, where automation and connectivity redefine traditional processes. By integrating advanced systems such as IoT and real-time data analytics, Trumpf demonstrates a commitment to enhancing operational efficiency and a desire to remain ahead of industry trends. These advancements allow for optimized production scheduling, reduced downtimes, and the ability to swiftly adapt to changing market demands, thereby offering a more agile and responsive manufacturing environment. The factory’s focus on smart manufacturing is evident in every facet of its operations, showcasing how innovative technology can be harnessed to deliver cutting-edge manufacturing solutions.

As Trumpf continues to explore the potential of connected systems, the focus remains on enhancing productivity and maintaining quality. By leveraging big data, Trumpf gains valuable insights into its manufacturing processes, enabling more informed decisions and fostering continuous improvement. This data-driven approach amplifies Trumpf’s ability to predict and respond to potential disruptions, ensuring seamless operations. These strategic decisions are indicative of Trumpf’s commitment to staying at the forefront of technological progress, reinforcing its status as a leader in the manufacturing domain through proactive adoption and implementation of state-of-the-art technologies.

Sustainability and Industry Impact

The inauguration of Trumpf’s Smart Factory in Farmington, Connecticut, is a landmark in U.S. manufacturing evolution. As global industry needs continue to evolve, Trumpf’s decisive investment emphasizes its dedication to improving production processes by embracing automation and connectivity. This factory signifies more than just a rise in output; it marks a progressive shift towards the future of manufacturing, prioritizing adaptability and data-driven strategies. Renowned for its expertise in laser technology and metal fabrication machinery, Trumpf aims to strengthen local manufacturing capabilities, positioning itself at the forefront of innovation. This venture not only promises to boost regional industrial operations but also serves as a testament to integrating advanced technologies. By doing so, Trumpf is shaping the future pathways of manufacturing, focusing on creating smart, interconnected systems that are responsive to the ever-changing demands of the global market, paving the way for the industry’s next generation.