The landscape of industrial production in the UK is undergoing a profound transformation, driven by the rapid adoption of factory automation and industrial control systems that promise to redefine efficiency and competitiveness on a global scale. With a current market valuation of approximately $16 billion, projections indicate an impressive climb to $42.26 billion by 2034, reflecting a robust compound annual growth rate (CAGR) of 10.20% over the next decade. This surge underscores the pivotal role of advanced technologies in addressing modern manufacturing challenges, from cost reduction to meeting complex operational demands. As industries across the board embrace automation, the integration of smart solutions is not just a trend but a necessity for staying relevant in a fiercely competitive global market. The following discussion delves into the forces propelling this growth and the specific technologies shaping the future of manufacturing in the UK.

Driving Forces Behind Market Expansion

Manufacturing Sector Growth and Competitive Pressures

The expansion of the UK’s manufacturing sector stands as a primary catalyst for the booming factory automation market, as industries strive to enhance productivity amid intensifying competition. With sectors like automotive, pharmaceuticals, and food and beverage pushing for higher output, the demand for sophisticated systems to streamline operations has never been greater. Automation technologies offer a pathway to minimize human error, optimize resource use, and accelerate production cycles, which are critical for maintaining a competitive edge. The pressure to innovate is palpable, as companies recognize that adopting cutting-edge solutions is essential to meeting stringent quality standards and consumer expectations. This drive is further fueled by the need to adapt to fluctuating market demands, where flexibility in production processes becomes a key differentiator for success.

Beyond immediate operational benefits, the competitive landscape compels manufacturers to invest in automation as a long-term strategy for sustainability and growth. The integration of systems that can handle intricate tasks with precision allows businesses to scale operations without proportional increases in costs. Additionally, the push for automation aligns with broader economic goals of revitalizing industrial hubs in the UK, creating a ripple effect of job creation in tech-driven roles while reducing dependency on manual labor for repetitive tasks. This shift not only enhances efficiency but also positions the UK as a leader in adopting forward-thinking industrial practices, setting a benchmark for others to follow in the global arena.

Rising Demand for Advanced Systems

A significant driver of market growth is the increasing reliance on Manufacturing Execution Systems (MES), which play a crucial role in managing complex production workflows through meticulous planning and real-time tracking. These systems enable manufacturers to oversee every stage of production, ensuring that resources are allocated efficiently and bottlenecks are swiftly addressed. The ability to monitor processes with granular detail empowers companies to make data-driven decisions, ultimately improving output quality and reducing waste. As industries grapple with the intricacies of modern supply chains, MES emerges as an indispensable tool for maintaining operational coherence and meeting tight deadlines.

Equally transformative is the growing adoption of cloud-based solutions, which offer scalability and accessibility that traditional systems often lack. By leveraging cloud technology, manufacturers gain the flexibility to access critical data in real time from any location, facilitating seamless collaboration across teams and facilities. This approach also proves cost-effective, as it minimizes the need for extensive on-site infrastructure while providing robust security features to protect sensitive information. The convergence of MES and cloud solutions signals a shift toward more agile and responsive manufacturing environments, capable of adapting to rapid changes in market conditions with unparalleled efficiency.

Technological Innovations Shaping the Future

Impact of Machine Vision and Industry 4.0

Machine vision technology has emerged as a cornerstone of the UK’s factory automation market, holding a substantial share due to its versatile applications in quality control, assembly, and monitoring. Advances in sensor technology and algorithms have significantly improved the accuracy of these systems, enabling them to detect defects and ensure precision in high-speed production lines. This capability is particularly vital in industries like automotive, where even minor errors can lead to costly recalls or safety issues. By integrating machine vision, manufacturers can uphold stringent standards while reducing the likelihood of human oversight, thereby enhancing overall reliability in output.

The broader adoption of Industry 4.0 principles and the Industrial Internet of Things (IIoT) further accelerates the integration of smart technologies into manufacturing processes. These frameworks foster interconnected systems where machines communicate seamlessly, sharing data to optimize performance and predict maintenance needs before breakdowns occur. This level of connectivity transforms factories into intelligent ecosystems that can self-regulate and adapt to changing conditions with minimal human intervention. The synergy of machine vision with Industry 4.0 creates a powerful paradigm for innovation, positioning UK industries at the forefront of a global shift toward smarter, more resilient production models.

Sector-Specific Automation in Automotive and Beyond

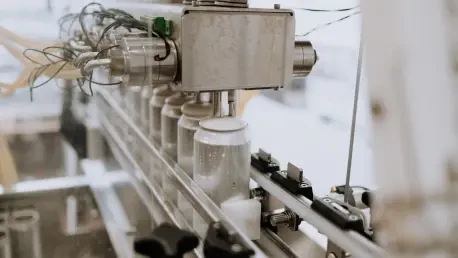

The automotive sector, a major pillar of UK manufacturing, exemplifies the transformative power of automation in addressing complex production demands. Processes such as assembly, welding, and painting have been revolutionized through robotic systems and control technologies, allowing for greater precision and speed in meeting rising consumer demand. Automation enables manufacturers to handle intricate designs and customization with ease, ensuring that even high-volume production maintains consistent quality. This sector’s reliance on advanced systems highlights their indispensable role in navigating the challenges of modern industrial landscapes.

Beyond automotive, industries like chemicals, pharmaceuticals, oil and gas, and utilities are also harnessing automation to enhance operational efficiency and safety. In these sectors, technologies such as Supervisory Control and Data Acquisition (SCADA) and Distributed Control Systems (DCS) provide critical oversight, ensuring that processes adhere to regulatory standards while minimizing risks. The versatility of automation solutions allows for tailored applications that address unique challenges across diverse fields, from maintaining sterile environments in drug production to optimizing energy use in utilities. This widespread adoption reflects a collective recognition of automation as a catalyst for progress, driving innovation across the industrial spectrum.

Reflecting on Transformative Growth

Looking back, the remarkable trajectory of the UK factory automation and industrial control systems market reveals a sector that adapted swiftly to technological advancements and pressing efficiency needs across various industries. The journey from a $16 billion valuation to a projected $42.26 billion by 2034 illustrates how automation became a linchpin for modern manufacturing challenges. Moving forward, stakeholders should focus on fostering collaborations between technology providers and manufacturers to accelerate the adoption of smart solutions. Prioritizing investments in scalable systems like cloud-based platforms and machine vision will be crucial for sustaining this momentum. Additionally, addressing skill gaps through targeted training programs can ensure that the workforce is equipped to handle increasingly sophisticated technologies, paving the way for continued innovation and competitiveness in the global market.