The United Kingdom’s manufacturing sector stands at a critical juncture where the widespread adoption of artificial intelligence is no longer an intriguing possibility but an absolute imperative for survival and sustained growth. While a select group of industry leaders has begun to harness the transformative power of AI, the sector as a whole is lagging dangerously behind, risking its competitive edge on an increasingly sophisticated global stage. For many, the journey into digital transformation has barely begun, yet the path forward is clear. Integrating a suite of smart technologies is now essential for revolutionizing legacy operations, sparking unprecedented innovation, and unlocking entirely new business models that will define the very future of modern manufacturing. The time for hesitation is over; the era of intelligent production is here, and British industry must either embrace it or be left behind in a world driven by data and automation.

A Divided Landscape of Pioneers and Laggards

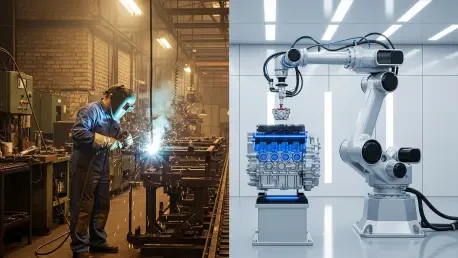

A stark dichotomy has emerged within the UK manufacturing industry, creating a tale of two vastly different sectors. On one end of the spectrum are the pioneering multinational corporations, with giants like Jaguar Land Rover (JLR) and Rolls Royce serving as powerful exemplars of AI’s strategic and practical value. JLR is already leveraging sophisticated tools like digital twins and generative AI to create dynamic digital advertising assets that respond to voice commands, and it envisions a future where consumers use the same technology to custom-configure vehicles. Similarly, Rolls Royce has deeply embedded AI technologies throughout its operational chain, from the initial stages of engine design to the critical task of turbine blade inspection. These examples illustrate a fundamental shift away from the traditional, linear, efficiency-centric production model toward a more dynamic and integrated system that heavily emphasizes automation, seamless data integration, and long-term sustainability, often leading to a revenue model of “servitization,” which supplements product sales with value-added services.

Despite the compelling successes of these industry leaders, a more sobering reality exists for the broader sector. A November 2024 research report revealed that the industry’s digital transformation remains a work in progress, with just over half of UK manufacturers categorized as “evolving” in their AI usage. This statistic implies that a substantial portion of the sector has yet to meaningfully embark on its AI journey, leaving untapped potential on the table. The report also uncovered the primary obstacles to adoption, with a significant knowledge gap being a major barrier; a mere 7 percent of respondents claimed to possess “good knowledge” of AI. Beyond this educational deficit, manufacturers point to the inherent complexity of AI systems, the substantial initial costs of implementation, and a variety of other technology-related issues as significant challenges that continue to impede widespread progress and stifle the innovation necessary to compete on a global scale.

The Transformative Power of Intelligent Integration

For those organizations capable of navigating these challenges, artificial intelligence offers the potential to revolutionize every facet of their operations with unparalleled precision and efficiency. On the factory floor, AI-powered solutions and robotics can automate a wide range of tasks, including welding, painting, material picking, and, crucially, the identification of product defects with superhuman accuracy. The benefits of this automation are twofold: it drastically reduces costs and saves time while simultaneously improving employee well-being by relieving human workers of tedious or hazardous tasks, allowing them to be redeployed to more sophisticated and value-added work. A prime example can be seen at JLR’s Coventry factory, where a quadruped robot now monitors high-tech equipment for electric vehicle development, freeing up highly skilled engineers to dedicate more time to critical analysis. Beyond the shop floor, AI tools are instrumental in optimizing the entire supply chain, creating a unified system that provides real-time visibility across all stages and allows for agile responses to market fluctuations.

Furthermore, AI’s capacity to gather, process, and analyze enormous quantities of data from diverse sources in real-time is creating previously unimaginable possibilities for product innovation. Manufacturers can now move beyond resource-intensive traditional methods like field research and instead deploy smart AI tools to rapidly collect a rich tapestry of information, including data from product performance, comprehensive market trend reports, and nuanced user sentiment gathered from service interactions and social media. This holistic approach provides a deep and dynamic understanding of customer needs and desires, forming a powerful foundation for developing next-generation products. This wealth of data then fuels the innovation process, with advanced analytics sifting through the information to identify the most desirable product attributes. These attributes are then translated into input parameters for generative AI models, which can churn out a multitude of creative and viable product design options at a speed and scale far beyond traditional human-led methods, significantly accelerating the entire innovation lifecycle.

Reshaping Business Models and Revenue Streams

The impact of artificial intelligence extends well beyond operational efficiency to fundamentally reshape business strategy, particularly through the enhancement of servitization. This model, where manufacturers offer product-related services to deepen customer relationships and create additional revenue streams, is powerfully exemplified by Rolls Royce’s pioneering “Power by the Hour” program. Today, AI supercharges this concept. Rolls Royce leverages AI and advanced analytics to collect and analyze real-time performance data—such as speed, temperature, and pressure—from its engines in operation around the world. This continuous stream of information allows the company to identify anomalous behavior and accurately predict maintenance requirements, enabling proactive service that minimizes costly downtime for its clients. Another AI solution analyzes parts demand and availability data to streamline inventory and shorten lead times, further enhancing the service offering. By transforming a product sale into a long-term service partnership, manufacturers can create more resilient and profitable business models.

Moreover, AI technologies are the critical backbone of modern digital marketplace platforms, which are creating vast ecosystems that connect producers, distributors, suppliers, marketing service providers, and consumers on a global scale. Within these intelligent marketplaces, manufacturers can forge strategic innovation and distribution partnerships to expand their business reach far beyond traditional boundaries. They can even establish direct-to-consumer (D2C) sales channels, bypassing intermediaries to build stronger brand relationships and capture greater profit margins. These platforms use AI to manage complex logistics, personalize customer experiences, and optimize pricing in real-time. By participating in or even creating these digital ecosystems, UK manufacturers can tap into new and lucrative revenue streams, diversify their market presence, and build a more agile and responsive business structure that is better equipped to handle the volatility of the global economy.

The Path Forward a Mandate for Action

The evidence presented a compelling case that artificial intelligence was a foundational technology capable of transforming every aspect of the manufacturing industry, from core operations and product innovation to overarching business models. While the UK manufacturing sector possessed leading innovators who demonstrated the immense potential of AI, it became clear that the majority of its constituents had only just begun to scratch the surface of what these technologies could offer. The analysis concluded with an urgent call to action, asserting that UK manufacturers had to accelerate their adoption of AI. This acceleration was framed not as a choice but as a necessity to overcome existing challenges, unlock profound value for their organizations, and deliver superior products and services to customers in an increasingly competitive global market. The future of British manufacturing, it was argued, depended on its willingness to embrace this technological revolution with strategy and conviction.