When a factory’s heartbeat is measured in milliseconds and decisions flow through control networks faster than mechanics can reach the line, even a brief sag on the power bus can cascade into ruined batches, scrambled data, and costly restarts that shake margins. Manufacturers have leaned into automation and real-time analytics to tame variability, yet those gains hinge on one unglamorous constant: stable, continuous electricity that keeps control logic, sensors, and communications alive. Programmable logic controllers, distributed control systems, and SCADA layers are only as credible as the electrons they ride on, and the margin between “routine” and “recovery mode” is often a fraction of a second. In that tight window, a purpose-built industrial UPS turns fragility into resilience, preserving state, context, and safe sequences while the grid hiccups or generators come online.

Control Intelligence Demands Power Integrity

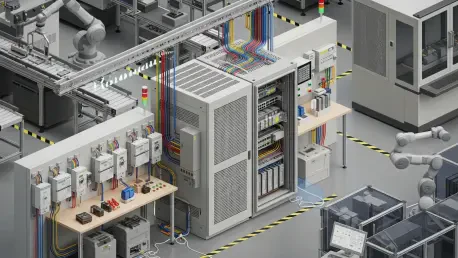

The modern plant operates as a coordinated ecosystem rather than a cluster of isolated machines, with controllers collecting field data, evaluating process thresholds, and dispatching commands that balance quality, throughput, and safety. PLCs run deterministic tasks at the edge, DCS platforms orchestrate continuous processes, and SCADA interfaces surface trends and alarms that guide interventions. This choreography only holds together when continuity is absolute; a brownout during a control cycle can freeze actuators mid-motion, corrupt historian entries, or trigger nuisance trips that require manual resets. Office-grade backup units were never meant for vibration, dust, and temperature extremes near the line, nor do they provide the ride-through headroom required for orderly state preservation. In short, operational intelligence collapses without power integrity to match its ambition.

Industrial-grade UPS platforms close that gap by stabilizing voltage, filtering surges, and delivering clean power long enough to bridge transfers or, if needed, execute graceful shutdowns that honor interlocks and purge cycles. By keeping control panels, edge gateways, time servers, and network switches online, they protect batch records, calibration data, and alarm histories that underpin traceability and compliance. Beyond uptime, soft landings reduce mechanical stress from abrupt stops, shorten recovery after disturbances, and temper energy waste by avoiding chaotic restarts. The picture grows smarter when monitoring tools tie directly into the UPS layer: telemetry enables anomaly detection, trend analysis, and predictive service for batteries and fans, turning maintenance from reactive to anticipatory. Load segmentation and prioritized shedding further align energy use with process criticality, strengthening both reliability and efficiency.

Building A Unified Power-Controls Strategy

Treating power quality as a first-class control variable reshaped how facilities planned upgrades and expansions, because the practical gains appeared wherever automation intersected with electrical stability. Control engineers evaluated which loops could tolerate brief interruptions and which demanded uninterrupted runtime, then mapped UPS coverage to those priorities. Critical components—PLC racks, safety relays, industrial PCs, time sync sources, and the network spine—received clean power domains, often with double conversion designs to decouple from upstream noise. The SCADA layer ingested UPS telemetry as native tags, so alarms reflected power health alongside process states, and historians preserved a synchronized view of both. With this alignment, short grid events ceased to be production events, and the line’s behavior stayed predictable.

Operational analytics also benefited once energy, condition monitoring, and control data shared a common context, because the root cause of an out-of-spec run was no longer ambiguous. Power anomalies that once appeared as “random” defects were traced to sags, harmonics, or switching transients, and mitigation moved from guesswork to targeted action. Maintenance teams scheduled battery replacements from state-of-health trends instead of time-based intervals, and UPS self-tests fed work orders before degradation reached the line. Meanwhile, balanced loads and sensible autonomy settings prevented oversizing, trimming lifecycle costs without eroding safety margins. Strategic partnerships with established energy and equipment providers reinforced that approach; solutions were vetted against industry standards, environmental constraints, and application-specific hazards, which elevated uptime and tightened compliance in audit-heavy sectors.

From Design Choice To Competitive Edge

The path forward had been straightforward once leadership framed power resilience and control intelligence as a single system, not two procurement lines. Teams classified processes by criticality, then right-sized industrial UPS coverage with clear autonomy targets—seconds for ride-through, minutes for state capture, longer where safe stops required purges or inerting. Network architects placed protected aggregation points and time servers under the same power envelope as controllers to keep determinism intact during transitions. Engineers folded UPS telemetry into SCADA and CMMS platforms so alarms, trends, and maintenance plans acted on the same truth. Procurement leaned on suppliers with proven industrial pedigrees, ensuring enclosures, cooling, and firmware aligned with plant realities rather than office assumptions.

The competitive upside became tangible once these choices settled in, because uptime steadied, scrap fell, and restart curves shortened across lines. Data integrity held through disturbances, which strengthened analytics, accelerated troubleshooting, and improved regulatory traceability. Energy goals were easier to hit when load segmentation and smarter shedding reduced chaotic cycles after grid events. Most importantly, safety systems retained authority even when conditions were least forgiving, because their power footprint was protected and tested. The next steps were clear: bake power-quality metrics into continuous improvement, extend protection to brownfield bottlenecks, and revisit autonomy as processes evolved. By treating UPS-backed control infrastructure as the bedrock of digital operations, plants translated resilience into predictable performance and lasting returns.