Overview of the Aerospace Additive Manufacturing Landscape

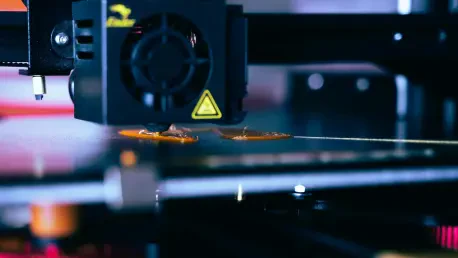

In the high-stakes world of aerospace, additive manufacturing has emerged as a game-changer, with the industry increasingly relying on this technology to craft intricate, mission-critical components that traditional methods struggle to produce. Imagine a world where lightweight, complex parts for spacecraft or fighter jets are created with unprecedented precision, slashing lead times and costs while meeting the rigorous demands of both commercial and defense applications. This is the reality today, as the sector leverages 3D printing to revolutionize design and production.

The aerospace additive manufacturing market spans key segments such as prototyping and high-volume production, each driven by technological advancements like enhanced material capabilities and faster printing speeds. Major players, including Velo3D, are at the forefront, pushing boundaries with solutions that cater to the sector’s unique needs. Stringent industry standards, however, govern every step, ensuring that innovations meet rigorous safety and reliability benchmarks critical to flight and defense systems.

Beyond innovation, the competitive landscape is shaped by a need for compliance and scalability. As aerospace companies prioritize suppliers who can deliver consistent quality at scale, certifications and adherence to global standards become non-negotiable. This dynamic environment underscores the importance of firms that not only innovate but also align with the sector’s exacting requirements, setting the stage for transformative growth.

Velo3D’s Milestone: Achieving AS9100D Certification

Significance of the Certification

Velo3D, a Fremont, California-based leader in advanced additive manufacturing, has recently secured the AS9100D certification for its Rapid Production Solution (RPS) Quality Management System, a benchmark recognized globally for quality in aviation, space, and defense supply chains. Administered by the Eagle Certification Group, this standard validates that a company’s processes meet the strictest requirements, ensuring products are safe and dependable for critical applications.

The certification highlights the strength of Velo3D’s RPS in delivering reliability, repeatability, and traceability—key attributes for aerospace manufacturing. This solution stands out by enabling a seamless shift from experimental prototyping to large-scale production without sacrificing precision. The rigorous audit process evaluated every facet of Velo3D’s operations, from documentation to implementation, affirming its commitment to excellence in high-stakes environments.

Impact on Market Position and Growth

Achieving this certification significantly boosts Velo3D’s credibility, positioning it as a trusted partner for aerospace primes, defense contractors, and government agencies that mandate compliance with such standards. This milestone opens doors to high-value contracts and collaborations, strengthening its foothold in a competitive market where trust and proven quality are paramount.

Dr. Arun Jeldi, CEO of Velo3D, noted that this achievement not only validates their dedication to meeting top-tier aerospace standards but also paves the way for substantial growth. With access to broader markets, especially in defense and space exploration, the company anticipates expanding its reach globally, capitalizing on the rising demand for certified manufacturing solutions.

This development also aligns with Velo3D’s mission to enhance US-based manufacturing resilience. By offering a certified pathway to scaled production, the firm is well-placed to support domestic supply chains, addressing both economic and strategic priorities in the aerospace sector over the coming years.

Challenges in Aerospace Manufacturing and Quality Assurance

The aerospace industry presents unique challenges, where the margin for error is virtually nonexistent due to the critical nature of components used in aircraft and spacecraft. Meeting these high-stakes demands requires exceptional technological precision, as even minor deviations can compromise safety and performance. Manufacturers must navigate complex design requirements while ensuring every part withstands extreme conditions.

Scalability adds another layer of difficulty, as transitioning from small-batch prototyping to high-volume production often reveals inconsistencies in processes or materials. Compliance with strict regulations further complicates operations, demanding robust systems to track and verify every stage of manufacturing. These hurdles test the limits of both technology and organizational capability in the sector.

To address such obstacles, companies like Velo3D implement innovative solutions, such as advanced software for real-time monitoring and integrated quality management systems. By prioritizing adaptability and investing in cutting-edge tools, they aim to balance innovation with regulatory adherence, ensuring that growth does not come at the expense of reliability or safety.

The Role of Regulatory Standards in Aerospace Innovation

Regulatory standards like AS9100D play a pivotal role in shaping aerospace manufacturing, acting as a cornerstone for safety and reliability across the industry. These guidelines ensure that every component, from engine parts to structural elements, meets consistent quality thresholds, fostering trust among stakeholders and end-users who depend on flawless performance in extreme environments.

Compliance with such standards influences broader industry practices, encouraging a culture of accountability and continuous improvement. For customers, certifications provide assurance that suppliers prioritize quality over shortcuts, while for companies like Velo3D, they serve as a competitive differentiator, distinguishing them in a crowded market where reputation is everything.

Moreover, adherence to these benchmarks drives innovation by setting clear expectations that push manufacturers to refine their processes and technologies. As a result, standards not only safeguard operations but also catalyze advancements, ensuring that the pursuit of cutting-edge solutions aligns with the overarching goal of delivering secure, dependable products.

Future Outlook for Velo3D and Aerospace Manufacturing

Looking ahead, additive manufacturing in aerospace is poised for significant evolution, with trends pointing toward greater scalability and integration of advanced materials to meet diverse application needs. From 2025 to 2027, industry forecasts suggest a surge in demand for certified production solutions as space exploration and defense initiatives expand, requiring suppliers who can deliver at pace without compromising quality.

Emerging disruptors, such as breakthroughs in automation and artificial intelligence, could reshape the competitive landscape, challenging established players to adapt swiftly. Global economic conditions, including supply chain constraints and geopolitical factors, may also impact growth trajectories, necessitating agile strategies to mitigate risks and seize opportunities in volatile markets.

Velo3D stands to play a strategic role in this future, leveraging its certified RPS to support US manufacturing resilience amid these shifts. By focusing on innovation and partnerships with key industry leaders, the company is well-positioned to address growing needs, potentially setting new benchmarks for efficiency and reliability in aerospace production.

Conclusion: Velo3D’s Path Forward in Aerospace Excellence

Reflecting on this milestone, Velo3D’s attainment of AS9100D certification marks a defining moment in its journey, affirming its dedication to quality and innovation within the aerospace and defense sectors. The rigorous validation of its processes underscores a commitment to meeting the highest industry standards, setting a strong foundation for future endeavors.

Moving forward, the company needs to capitalize on this achievement by forging strategic alliances with aerospace primes and government entities, ensuring it remains at the forefront of mission-critical manufacturing. Exploring advancements in scalable technologies and maintaining a laser focus on compliance will be essential steps to sustain momentum.

Additionally, addressing global supply chain challenges through localized production capabilities offers a pathway to bolster resilience. By continuing to push the envelope on additive manufacturing solutions, Velo3D has the opportunity to not only expand its market presence but also redefine standards of excellence in a rapidly evolving industry.