Formnext 2024, the premier 3D printing exhibition held annually in Frankfurt, Germany, showcased a vibrant array of innovations and trends despite market uncertainties and industry consolidations. This year’s event highlighted significant advancements across several key themes, reflecting the dynamic and forward-looking nature of the industry.

Focus on Sustainability

Advancements in Sustainable Materials

Sustainability was a prominent theme at Formnext 2024, with numerous companies showcasing their latest improvements in sustainable practices. Since its inception, 3D printing technology has long been touted as a potential sustainable alternative to traditional manufacturing methods. However, the industry acknowledges that more efforts are necessary to fully recognize and demonstrate its environmental benefits. This year, suppliers presented a range of innovative solutions to enhance sustainability. EOS took a significant step in this arena by introducing its HighReuse materials line, featuring ALM PA 950 HD and PA 2220, which boast recycling rates of up to 80% and 70% respectively. Stratasys pushed the boundary further with its launch of the SAF ReLife software upgrade for its H series machines, enabling the reuse of waste PA12 powder from any 3D printing process, including SLS and MJF, rather than discarding it. Another notable advancement came from Evonik, which presented its flame-retardant PA12FR material, now capable of 50% reusability with HP Multi-Jet Fusion 3D printers, offering a cost-effective alternative for parts like electronics housings and battery holders.

To further illustrate the depth of commitment to sustainability, companies such as ColorFabb showcased their new filaments created from industrial waste, including denim fibers and used polystyrene packaging, along with a fully biodegradable material. This demonstrated the brand’s dedication to sustainability through the creative use of industrial scraps. Advancements in traditionally power-intensive components like lasers were also evident. Meltio’s introduction of new blue laser technology, which consumes 30% less power and is significantly lighter, exemplified the industry’s move towards more energy-efficient solutions. These steps reveal the multifaceted approach the industry is taking to improve the sustainability of 3D printing.

Niche Recyclable Materials and Energy Efficiency

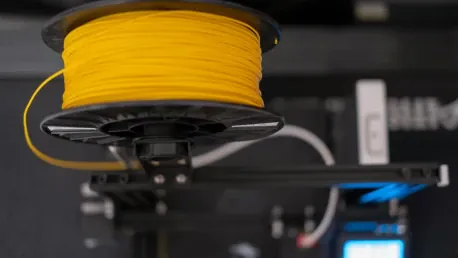

Formnext 2024 underscored the increasing importance of developing niche recyclable materials and promoting energy efficiency within the 3D printing industry. Companies seem intent on maximizing the potential of waste products, turning them into high-value materials that are both sustainable and functional. ColorFabb’s unveiling of new FDM filaments made from unconventional sources like denim fibers and used polystyrene packaging is a testament to this commitment. They also introduced a fully biodegradable material, reflecting an innovative approach to material science that prioritizes recycling and sustainability.

Even traditionally high-energy components of the 3D printing process are witnessing advancements in energy efficiency. Meltio’s new blue laser technology stands out as a prime example of this trend. By consuming 30% less power and being lighter, this technology signifies a shift towards more energy-efficient solutions in the 3D printing landscape. The broader goal for many companies at Formnext is to create a more sustainable ecosystem, not just through recycling materials but also by reducing the overall energy footprint of their technologies. These concerted efforts show a keen awareness of the need for such innovations in combating environmental challenges.

Getting the Spark Back

Technological Innovation Amid Industry Changes

Amid recent mergers and acquisitions that stirred the 3D printing industry, Formnext 2024 marked a resurgence in technological innovation, signaling a renewed emphasis among key players to push the technological envelope further. Major industry figures showcased a diverse array of upgrades and new materials at the event. Stratasys, for example, introduced numerous enhancements, including a new filament drying cabinet for its Fortus F900 machine and over 30 new materials tailored to its Origin P3 resin platform, reflecting its continued devotion to innovation and technological advancement.

3D Systems drew significant attention with its introduction of the PSLA 270, a high-speed, projector-based SLA 3D printer backed by the mature Figure 4 materials portfolio. This new machine represents a significant leap in SLA technology, making high-speed, high-precision 3D printing more accessible to a broader segment of the industry. Formlabs also attracted a substantial crowd eager to see the latest Form 4 and Form 4L printers, which further accentuated the brand’s renowned build quality and design. These moves by industry heavyweights underscore a renewed focus on innovation, aiming to overcome the technological barriers and deliver on the promise of transformative applications for 3D printing.

New Product Launches and Innovations

Besides reinforcing existing lines, the event also saw several groundbreaking product announcements that hinted at the future direction of the 3D printing industry. Stratasys, for instance, distinguished itself further with a slew of new material offerings designed to broaden the application horizon of their printing technologies. Similarly, 3D Systems and their PSLA 270 machine reinforced the belief that there is still plenty of scope for innovation in high-speed, high-precision 3D printing sectors, challenging conventional norms about what is achievable with contemporary technology.

Formlabs rallied a huge gathering drawn by the unveiling of the latest Form 4 and Form 4L printers, pointing out the brand’s long-standing commitment to superior build quality and cutting-edge design. These launches reveal an industry dynamic and forward-looking, constantly pushing the frontier of what 3D printing can accomplish. As exemplified by these innovations, this year’s Formnext paved the way for technological leaps that promise to reshape the industry and pave the way for new, transformative applications.

Has Desktop FDM Peaked?

Market Saturation and Shifts in Focus

A notable theme at Formnext 2024 centered around the apparent plateau in desktop FDM (Fused Deposition Modeling) machine development. The desktop FDM market seems to be reaching saturation, with brands fiercely competing on price and performance factors. Noteworthy names like Bamboo Labs and Prusa have significantly established their footprint in this domain, creating a highly competitive marketplace that leaves little room for additional standalone innovation. Given these dynamics, it was particularly striking that no new desktop FDM launches emerged from major western brands at the event, implying a potential peak or a pivot in interest within this segment.

This apparent stagnation in new desktop FDM developments may be hinting at a broader industry shift. The absence of groundbreaking releases suggests that companies might be redirecting their focus towards more specialized industrial applications. As the market for consumer and small-scale professional FDM printers becomes increasingly saturated, the need to distinguish products based on more advanced and specialized capabilities seems more pronounced.

Targeting Industrial Applications

In line with the shift away from consumer-level FDM machines, brands such as UltiMaker are moving towards targeting more industrial applications. UltiMaker, which resulted from the merger of two pioneering small-format FDM companies, illustrated this shift with the Factor 4 machine. This model comes outfitted with advanced features typically associated with industrial-grade equipment, indicating a strategic maneuver to meet the rigorous requirements of factory floors more than those of design studios or home workshops.

This repositioning towards industrial applications is likely motivated by the superior margins, demand for more sophisticated technology, and the need for equipment capable of withstanding the rigors of continuous, high-volume production. By targeting factory floor requirements, companies can cater to a market segment that values durability, performance, and customization capabilities in their 3D printing solutions. This strategic pivot underscores a broader industry trend where the future of FDM may not lie in consumer desktops but in robust, industrial-grade applications capable of contributing significantly to large-scale manufacturing processes.

Slicker Software

Importance of Software in Additive Manufacturing

The Formnext 2024 event placed significant emphasis on the growing importance of software in additive manufacturing, transitioning the narrative from hardware to more integrated, efficient, and intelligent software solutions. This pivot spotlighted how software innovations are becoming central in enhancing design, process control, and simulation capabilities. Companies such as Synera and Cognitive Design Systems unveiled groundbreaking solutions aimed at automating workflows and advancing generative design processes. These technologies underscore a forward-looking approach where software plays a pivotal role in optimizing additive manufacturing capabilities.

The increasing focus on sophisticated software solutions reflects the shifting interests of Formnext attendees towards gaining competitive edges through advanced software integrations. The keen interest in these offerings delineates how crucial software has become, not just in managing hardware but in enhancing efficiency, creativity, and precision within the additive manufacturing realm. This transition marks a significant evolution from purely hardware-centric demonstrations to a more nuanced understanding of how integrated software solutions can redefine the boundaries of what is achievable in 3D printing.

Legal Skirmishes and Established CAD Companies

An interesting subplot amid the software advancements at Formnext 2024 was the legal skirmish involving the China-based software company VoxelDance. Their exhibit was halted by German customs investigators over allegations of IP infringement, putting the spotlight on the complexities of intellectual property in high-tech industries. While the outcome of this dispute remains pending, it highlights the ongoing challenges companies face in safeguarding innovations while operating in a highly competitive and globalized market.

Meanwhile, established CAD companies like Catia, Onshape, Siemens, and Autodesk showcased their moves to integrate additive manufacturing workflows into their existing platforms. Their efforts aimed to challenge the dominance of specialist software such as Materialise’s Magics. Contributions from Tech Soft 3D and Visionware 3D highlighted how foundational these key technologies and turnkey services are to many additive manufacturing processes. This underscores the increasing integration and complexity of the software ecosystem that supports the 3D printing industry, pushing it towards more holistic and seamless production solutions.

Fresh Attempts to Deliver on Earlier Promises

Advances in Color 3D Printing

Formnext 2024 witnessed ambitious efforts by companies trying to deliver on long-standing promises of advancements in color 3D printing and 3D printed electronics. Stratasys notably collaborated with Italian packaging expert Baralan to develop methods for 3D printing in full color on glass containers using their PolyJet technology. This collaboration allowed for intricate textures and vibrant designs that provided bespoke details for luxury products and short production runs. These designs were achieved through a bespoke primer and protective coating, demonstrating the potential for real-world application of color 3D printing technology.

Other companies, such as Mimaki, which is recognized for its expertise in color accuracy, displayed prototypes and models that showcased lifelike realism. Mimaki’s dedication to achieving industry-standard, repeatable colors in 3D printing was evident in their showcased works. By pushing the boundaries of color fidelity and detail in 3D printed models, these innovations pointed towards the growing potential for additive manufacturing to meet the stringent aesthetic and functional demands of various industries, particularly in fields such as consumer goods and decorative arts.

Innovations in 3D Printed Electronics

Formnext 2024, the leading exhibition for 3D printing, held its annual event in Frankfurt, Germany, presenting an impressive range of innovations and emerging trends in the face of market uncertainties and industry consolidations. This year’s exhibition underscored remarkable advancements across several critical themes, demonstrating the dynamic and forward-thinking character of the 3D printing industry.

The event spotlighted groundbreaking technologies, such as improved additive manufacturing processes, which promise faster and more precise production capabilities. Attendees were particularly excited about the integration of artificial intelligence in 3D printing, which is paving the way for smarter, more efficient production lines. Furthermore, there was significant focus on sustainable practices, with multiple exhibitors showcasing eco-friendly materials and energy-efficient technologies.

The healthcare sector also made a strong showing at Formnext 2024. Innovations in bioprinting and customized medical implants highlighted the potential of 3D printing to revolutionize patient care. Additionally, developments in metal 3D printing created buzz, particularly due to their implications for automotive and aerospace industries.

Networking opportunities abounded, allowing professionals to share insights and foster collaborations that can drive the industry forward. Despite the challenges faced by the market, Formnext 2024 stood as a testament to the resilience and relentless pursuit of innovation within the 3D printing community. Overall, the event painted a hopeful picture of the future, brimming with potential and poised for continued growth and transformation.