In an era where manufacturing efficiency and precision are paramount, the unveiling of groundbreaking technology can redefine industry standards overnight. At the Discover 2025 event, held from October 6-10 at Mazak’s facility in Florence, Kentucky, a new benchmark has been set with the introduction of a revolutionary multi-tasking machine. This innovation promises to transform production processes by combining multiple operations into a single setup, addressing long-standing challenges like extended lead times and inconsistent part quality. Manufacturers across various sectors are keenly observing how such advancements can streamline workflows while maintaining the highest standards of accuracy. The spotlight is on a machine that not only enhances operational capabilities but also integrates cutting-edge digital tools to meet modern demands. This development marks a significant step forward in the pursuit of smarter, more adaptable manufacturing solutions.

Unveiling Cutting-Edge Capabilities

Revolutionizing Multi-Tasking Operations

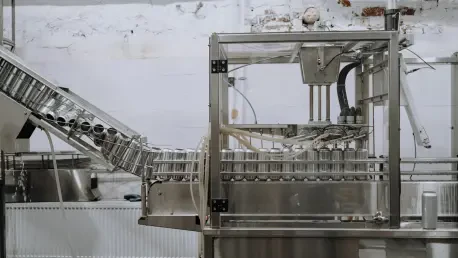

At the heart of this technological leap is a machine that integrates turning, milling, and, for the first time, grinding operations within a single setup. This all-in-one approach eliminates the need for multiple machines, drastically reducing handling and setup times while enhancing process reliability. The design prioritizes thermal stability, ensuring consistent performance even under varying environmental conditions. Such a feature is crucial for industries where exacting tolerances and superior surface finishes are non-negotiable. By completing parts in one go, manufacturers can achieve significant efficiency gains, slashing lead times and minimizing errors that often arise from transferring workpieces between different equipment. This innovation reflects a growing trend toward consolidated machining solutions that cater to the complex needs of modern production environments, setting a new standard for what multi-tasking can achieve.

Power and Precision in Design

Beyond its operational versatility, the machine showcases impressive technical specifications that cater to large-scale and intricate projects. Equipped with dual turning spindles and a milling spindle headstock, it supports a 10-inch chuck and offers substantial axis strokes to handle parts up to 26.38 inches in diameter. The spindles deliver robust performance with speeds up to 4,000 rpm for turning and optional milling speeds reaching 20,000 rpm, backed by a powerful 24 hp/22 kW output. Capable of processing parts up to 98 inches long through varied bed configurations, this equipment is tailored for diverse applications. Such capabilities ensure that manufacturers can tackle ambitious projects without compromising on precision or speed, addressing a critical need for scalability in production. This design underscores a commitment to meeting the evolving demands of industries that require both power and finesse in their machining processes.

Embracing Digital and Automation Trends

AI-Driven Control for Optimized Performance

Central to the machine’s appeal is its advanced control technology, which leverages artificial intelligence to elevate machining outcomes. Features like automatic program generation from 3D models, vibration reduction through sensor-based spindle adjustments, and adaptive responses to environmental heat changes ensure unparalleled accuracy. These AI-powered tools facilitate faster programming and deliver superior surface finishes, addressing common pain points in precision manufacturing. The integration of such technology not only streamlines operations but also enhances consistency, allowing manufacturers to maintain tight tolerances with ease. This focus on intelligent control systems highlights a broader shift in the industry toward data-driven solutions that optimize every aspect of the production process, ensuring that even the most complex tasks are executed with precision and efficiency.

Digital Twins and Automation Flexibility

Another standout aspect is the seamless integration with software that creates digital twins of physical machines, bridging the gap between virtual and real-world operations. This digital replication enables efficient job setups and interactive CAD/CAM interfaces, empowering manufacturers to simulate and refine processes before execution. Additionally, the machine supports various automation strategies with flexible configurations, such as front-mounted tool magazines for easy integration with gantry loaders or options for rear-mounted setups and robot interfaces. This adaptability ensures that production environments can be customized to specific needs, enhancing throughput and reducing bottlenecks. The emphasis on digitalization and automation reflects an industry-wide push toward smarter manufacturing ecosystems, where technology and flexibility converge to drive productivity and innovation in equal measure.

Reflecting on a Milestone in Manufacturing

A Leap Toward Industry Excellence

Looking back at the reveal during the Discover event, the impact of this multi-tasking machine was undeniable as it captured the attention of industry professionals. Its ability to combine multiple processes into a single setup, paired with robust automation options, marked a pivotal moment for manufacturing efficiency. The integration of AI-driven controls and digital tools further solidified its position as a game-changer, offering solutions that addressed real-world challenges like production delays and quality inconsistencies. This unveiling demonstrated how far technology has come in meeting the rigorous demands of modern production, setting a precedent for future innovations. Manufacturers witnessed a tool that not only improved output but also redefined operational standards, paving the way for more streamlined and reliable workflows.

Charting the Path Forward

As the industry reflected on this advancement, the focus shifted to actionable next steps for leveraging such technology. Manufacturers were encouraged to explore how integrating advanced multi-tasking solutions could address specific production hurdles, from reducing lead times to enhancing part quality. The adaptability of automation configurations offered a blueprint for tailoring setups to unique operational needs, while digital tools provided a foundation for smarter decision-making. Moving forward, the challenge lay in scaling these innovations across diverse sectors, ensuring that the benefits of precision and efficiency reached a wider audience. The legacy of this machine’s debut was a reminder of the transformative potential within manufacturing, urging stakeholders to invest in technologies that promise not just incremental gains but a fundamental reimagining of what production can achieve.