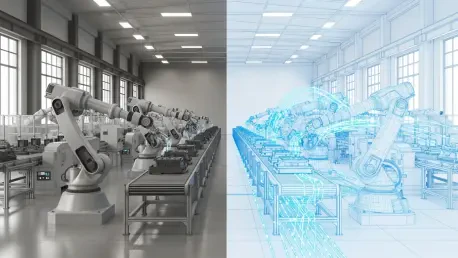

The long-held industrial dream of a perfectly optimized factory operating flawlessly from its very first day is rapidly moving from theoretical aspiration to tangible reality. This monumental shift is not the result of incremental improvements but of a foundational change in how industrial systems are designed, built, and operated. At the heart of this transformation is the digital twin, a virtual replica of a physical asset, process, or system. A landmark collaboration between industrial and technology leaders is now scaling this concept to entire factories, promising to eliminate costly errors and unlock unprecedented efficiency before a single piece of equipment is ever installed on the factory floor.

A New Blueprint for Industrial Perfection

For decades, manufacturing has been bound by the high stakes of physical trial and error. Commissioning a new production line or retrofitting a plant involved significant capital investment, prolonged downtime, and the inherent risk of unforeseen bottlenecks or design flaws emerging only after implementation. Correcting these issues post-launch leads to budget overruns and delayed production, impacting a company’s ability to compete effectively in a fast-paced global market.

A new paradigm, however, is emerging to dismantle this legacy of risk. By creating and validating entire production ecosystems in a virtual environment, companies can now navigate complexity with remarkable foresight. The collaboration between Siemens and NVIDIA exemplifies this virtual-first approach, providing the tools to build, simulate, and optimize a factory in the digital realm. This allows engineers and operators to identify and resolve potential problems, test different layouts, and perfect workflows with a degree of precision that was previously unattainable.

The Industrial Metaverse Beyond the Hype

Far from the consumer-focused visions of virtual social spaces, the industrial metaverse represents a practical convergence of the physical and digital worlds to solve pressing industrial challenges. Modern manufacturing grapples with unprecedented complexity, fragile global supply chains, and an urgent need for greater sustainability and resource efficiency. These are not problems that can be solved by isolated improvements; they demand a holistic, data-driven understanding of the entire operational landscape.

This is where the concept of “true industrial intelligence” comes into play. The partnership between Siemens and its technology counterparts is focused on creating more than just static 3D models. The goal is to develop dynamic, physics-based digital twins that are continuously fed with real-time data from their physical counterparts. This living virtual environment becomes a powerful sandbox for testing, learning, and predicting outcomes, transforming how organizations approach everything from process design to long-term strategic planning.

Technology at the Core of Virtualization

The engine driving this revolution is Siemens’ Digital Twin Composer, a sophisticated technology developed to build large-scale, high-fidelity virtual environments. Built using NVIDIA Omniverse libraries, this platform serves as a powerful aggregator, capable of synthesizing immense volumes of data into a cohesive and interactive digital replica. It marks a significant step forward from basic simulations toward fully immersive and functionally accurate industrial metaverses.

The process begins by combining comprehensive digital twin data, which includes everything from 2D engineering schematics to detailed 3D CAD models of machinery. This static information is then enriched with real-time physical data streamed from sensors on the factory floor. The result is a photorealistic, physics-aware 3D experience where stakeholders can visualize and interact with the entire operation. This enables teams to virtually commission equipment, simulate material flows, and train AI agents to discover optimal production strategies, all within a risk-free digital space.

From Theory to Throughput with PepsiCo

Putting this advanced theory into practice, PepsiCo emerged as a key early adopter, trialing the technology across several of its U.S. manufacturing and warehouse facilities. The objective was to create a comprehensive digital twin that mirrored not only individual machine operations but the entire end-to-end supply chain. This virtual model included every conveyor, operator path, and pallet movement, all simulated with physics-level accuracy to reflect real-world conditions and constraints.

The results from this virtual-first approach were both immediate and substantial. By using the digital twin to test and validate new system configurations before physical deployment, PepsiCo achieved a 20% increase in throughput. The simulations also uncovered hidden capacity within existing layouts, leading to a 10-15% reduction in planned capital expenditure. Critically, the platform enabled the pre-emptive identification of up to 90% of potential operational issues, resulting in nearly 100% design validation and significantly accelerated project timelines.

A New Operational Framework for Manufacturing

The implementation of such powerful digital twins establishes a “digital thread” that weaves through the entire organization, connecting and unifying previously siloed departments. Information from design, engineering, operations, and logistics is integrated into a single source of truth, breaking down barriers and fostering cross-functional collaboration. This holistic view ensures that decisions made in one area are informed by their potential impact on the entire system.

This integration powers a strategic shift toward a virtual-first operational framework. Instead of committing to costly physical implementations based on theoretical models, companies can now fully validate and de-risk entire systems in the digital world. This move empowers organizations to accelerate production, enhance supply chain resiliency, and continuously optimize performance at a scale and speed that was once unimaginable, securing a decisive competitive advantage in the modern industrial era.

The successful application of this technology at an industrial giant like PepsiCo signaled a fundamental turning point. It demonstrated that the industrial metaverse was no longer a futuristic concept but a proven, practical tool for achieving tangible business outcomes. The quantifiable improvements in throughput, cost savings, and risk mitigation validated the virtual-first strategy, confirming that the path toward superior operational excellence was paved in the digital world long before the first piece of concrete was poured.