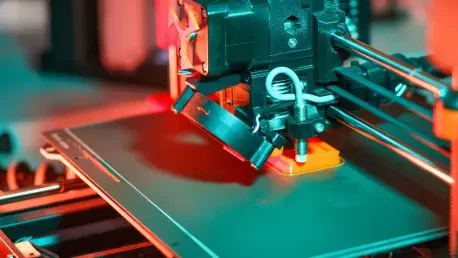

In a world increasingly driven by technological prowess, the need for innovative manufacturing solutions is ever-present. Additive Manufacturing (AM), particularly in 3D printing, stands at the forefront of this paradigm shift. This technology’s ability to reshape industries, from aerospace to healthcare, has positioned it as a pivotal element in modern manufacturing landscapes. AMEXCI’s unveiling of a new 3D printing facility in Örebro, Sweden, marks a noteworthy milestone and offers a glimpse into the broader trends and future directions of this dynamic industry.

Overview of the Additive Manufacturing Industry

The Additive Manufacturing industry is in a transformative phase, characterized by rapid advancements and expanding applications. Its significance lies in its ability to tailor production processes, reduce waste, and cut costs across a diverse range of sectors. Key players include technology giants and specialized firms, all contributing to the industry’s growth through innovative solutions. The landscape is shaped by both technological influences and evolving regulations aimed at ensuring safety and quality in this rapidly expanding field. Main segments, such as polymer-based 3D printing and metal additive manufacturing, continue to expand, propelled by breakthroughs in materials and processes.

Current Trends in Additive Manufacturing

Technological and Market Trends

Emerging technologies are continually redefining the boundaries of what Additive Manufacturing can achieve. Innovations such as multi-material printing, enhanced design capabilities, and faster production times are influencing market dynamics. Consumer behavior leans heavily toward customization and rapid prototyping, driving demand for AM solutions. Market drivers such as the push for supply chain efficiency and global shifts towards sustainable manufacturing are creating ripe opportunities for growth within the sector.

Market Analysis and Growth Projections

Current market data suggests robust growth ahead, fueled by the acceleration of technological adoption and broadening application scope. Analysts project substantial increases in market share, particularly in areas that benefit from specialized solutions such as medical implants and aerospace components. Growth projections extend significantly beyond 2025, indicating a sustained upward trajectory in sales and technology integration into various sectors. Performance indicators similarly point to enhanced profitability and expansion opportunities for companies investing in AM.

Challenges Facing the Additive Manufacturing Industry

Despite significant advancements, the industry grapples with several challenges that could hinder its progress. Technical limitations, such as print speed and material variability, remain key hurdles. Further complicating the landscape are regulatory challenges and market-driven obstacles, including competition, cost considerations, and consumer education. Addressing these through innovation, collaboration, and adaptive strategies will be crucial for the industry’s continued evolution and success.

Regulatory Environment and Compliance

The regulatory landscape of additive manufacturing is a complex web of laws and standards that impact industry practices. Compliance is essential to navigate through the stringent regulations governing AM processes, particularly in industries like healthcare and aerospace, where safety and efficacy are paramount. Recent changes in regulatory measures have underscored the importance of security protocols and quality assurance systems, shaping both current practices and future developments.

Future Outlook of the Industry

The future of Additive Manufacturing looks promising, with innovation at its core. Emerging technologies, such as AI-powered design tools and bioprinting, represent potential disruptors that could redefine the industry. Consumer preferences are expected to lean more towards personalized and sustainable solutions, driving demand for advanced AM techniques. Key growth areas may include biofabrication and advanced industrial applications, influenced by global economic conditions and an ever-increasing emphasis on sustainability and efficiency.

Conclusion and Strategic Recommendations

The new facility by AMEXCI not only cements its role as a leader in 3D printing but also serves as a beacon of the industry’s forward momentum. As the industry continues to grow, strategies focusing on overcoming current challenges and leveraging technological advancements will be vital. Stakeholders should invest in R&D, foster collaborations, and remain vigilant of regulatory developments to sustain growth. The future holds exciting opportunities, and companies positioned to innovate and adapt will likely reap substantial rewards. By navigating the complexities of this evolving landscape, AMEXCI is poised to shape and drive the industry toward new frontiers.