The Promise and Peril of a Medical Revolution

Cell and gene therapies stand at the forefront of a medical revolution, offering the potential to cure diseases once considered untreatable. Yet, this groundbreaking sector is caught in a profound paradox. While the science is delivering unprecedented therapeutic breakthroughs, the manufacturing and commercial models required to bring these treatments to patients are faltering. The industry is now facing a critical inflection point, characterized by a jarring split between market retreat and aggressive technological advancement. This article will explore this bifurcation, analyzing why traditional manufacturing is failing and investigating the growing consensus that automation may be the only viable path to secure the future of these life-saving innovations.

From Scientific Breakthrough to Industrial Bottleneck

The journey of cell and gene therapy has been one of remarkable scientific achievement. Early successes fueled a wave of optimism and investment, positioning CGT as the next frontier in medicine. This initial “high-growth” phase spurred the rapid expansion of development and manufacturing capabilities. However, the unique complexity of these living medicines proved to be a formidable challenge. Unlike traditional pharmaceuticals, CGTs often involve highly personalized, intricate, and labor-intensive production processes. The initial expectation that existing manufacturing paradigms could simply be adapted has met a harsh reality, revealing that the very methods that enabled early clinical success are now the primary barriers to commercial scale and affordability.

The Manufacturing Crisis: Why the Old Model Is Breaking

The Great Contraction: CDMOs Retreat Amidst Sobering Realities

The strain on the traditional manufacturing model is no longer theoretical. A significant market correction is underway, evidenced by the strategic retreat of major contract development and manufacturing organizations (CDMOs). Charles River Laboratories, for instance, is closing a cell therapy facility it acquired just a few years ago, while Catalent is shuttering its Belgian center. These moves are not isolated incidents but symptoms of a larger problem: the high cost of development and operational complexity have created overcapacity and weaker-than-expected demand. The initial rush to build capacity has collided with the economic unsustainability of the underlying processes, forcing key players to downsize and re-evaluate their commitment to the sector.

From Lab Bench to Assembly Line: The Unsustainable Cost of Complexity

The core of the manufacturing crisis lies in its reliance on archaic, manual operations. As articulated by the Alliance for Regenerative Medicine (ARM), the current paradigm depends heavily on highly skilled experts performing delicate tasks in open, clean-room environments. This approach is not only incredibly expensive but also introduces significant risks of product variability and contamination, making it fundamentally unscalable. Each batch becomes a bespoke, artisanal product rather than a consistently manufactured medicine. This inherent lack of standardization makes it nearly impossible to lower costs or meet the potential demand of a global patient population, trapping these revolutionary therapies in a cycle of high cost and limited access.

The Industrialization Imperative: Shifting from Science to Scale

This operational gridlock has led to a crucial shift in perspective across the industry. The primary barrier to curing patients is no longer purely scientific; it is now overwhelmingly industrial. Innovators like Cellares, which recently raised $257 million to build automated “smart” factories, argue that the challenge has evolved from discovering therapies to producing them reliably and affordably. This sentiment highlights a growing consensus that the future of CGT hinges not on the next biological discovery, but on an engineering and manufacturing revolution. The sector must transition from a craft-based approach to a truly industrialized one to survive.

The Factory of the Future: Automation as the Path Forward

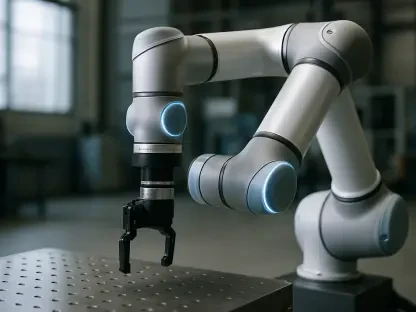

In response to the manufacturing crisis, the industry is converging on a definitive solution: automated, closed, and digitized production. This vision of the “factory of the future” replaces manual clean-room labor with robotic systems that can perform complex tasks within a self-contained, sterile environment. Forward-thinking companies are attracting substantial investment to make this vision a reality. Collaborations like the one between AstraZeneca and Multiply Labs to develop robotic systems for scalable cell therapy production underscore this trend. By embracing automation, companies aim to drastically reduce labor costs, minimize human error, improve product consistency, and ultimately create a manufacturing process that can be scaled to meet global demand.

A Blueprint for Success: Navigating the Transition to Automated Manufacturing

The path forward requires a decisive pivot. For CGT developers and manufacturers, the key takeaway is that clinging to traditional, manual processes is a failing strategy. The first actionable step is to invest in and integrate automated, closed-system technologies into the manufacturing workflow. This involves not only adopting robotics but also embracing digitization to monitor and control every step of the process, ensuring quality and consistency. Companies should prioritize partnerships with technology innovators specializing in bioprocess automation to accelerate this transition. By doing so, they can build a scalable and commercially viable model capable of delivering on the immense promise of their therapies.

A Verdict on Viability: Automation Isn’t Just an Option—It’s a Necessity

The cell and gene therapy sector is at a crossroads where its brilliant scientific potential is threatened by its industrial limitations. The ongoing market correction, marked by the retreat of established manufacturers, serves as a stark warning that the old way of doing things is no longer sustainable. The future belongs to those who embrace the industrialization imperative. Automation is not merely an efficiency upgrade; it is the foundational technology required to solve the sector’s most pressing challenges of cost, scale, and consistency. For these revolutionary treatments to become accessible medicines rather than niche miracles, the industry must fully commit to building the automated factory of the future.