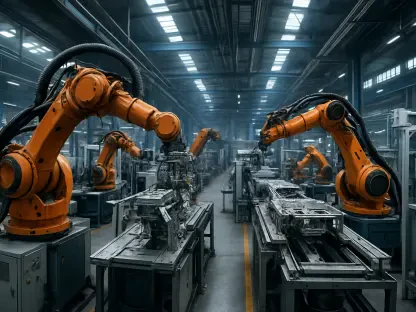

Continuous manufacturing is revolutionizing the pharmaceutical industry, offering a smarter, more efficient way to produce medications. This approach promises to streamline drug production processes, significantly enhancing efficiency, sustainability, and quality. However, the transition from traditional batch manufacturing represents not just an operational shift but also a cultural shift for pharmaceutical companies. As the industry responds to increasing pressures for cost reduction and enhanced quality control, continuous manufacturing stands as a beacon for future innovation.

The Driving Force Behind Continuity

Continuous manufacturing’s capacity to deliver improved production yields while optimizing the use of space, labor, and raw materials makes it a pressing topic for stakeholders. Recognized for its energy efficiency, it promises substantial cost savings and eco-friendly operations. The analysis herein will unpack the transformative potential of this manufacturing method, emphasizing how it directly addresses modern challenges and sets industry players on a path toward sustainable production practices.

Unpacking Market Trends and Projections

The pharmaceutical sector has witnessed notable technological milestones over the years, gradually shifting toward more advanced manufacturing methods. With the evolution from batch to continuous processes, companies such as Thermo Fisher Scientific have demonstrated remarkable improvements in efficiency and quality. Industry surveys, like the one conducted by CRB’s Horizons: Life Sciences, reveal that a significant percentage of industry leaders plan to fully embrace continuous technologies within the next five years, signaling a dramatic shift in market dynamics.

Transition Dynamics and Industry Adoption

The leap from batch to continuous processes encounters both challenges and considerable benefits. The case of Thermo Fisher Scientific illustrates how continuous manufacturing has fostered advancements in operational efficiency, drawing attention for its real-time quality monitoring capabilities. Despite industry conservatism and initial investment hurdles, continuous processes are gaining traction, as evidenced by the increasing number of companies willing to transition toward this innovative method.

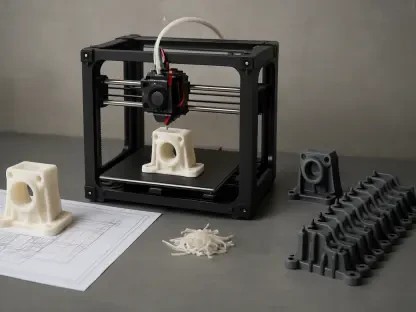

Technological Innovation and Its Impact

Advancements in technologies such as process analytical tools and vacuum granulation systems have revolutionized drug product manufacturing, providing unprecedented control and precision. Meanwhile, drug substance manufacturing, particularly involving complex chemical processes, encounters greater obstacles that require continuous industry commitment and innovation. These advancements are paving the way for other sectors within pharmaceuticals, such as biologics, to explore the benefits of continuous manufacturing.

Regional Differences and Emerging Technologies

Geographical variations complicate the widespread adoption of continuous manufacturing. Different regions present unique regulatory landscapes and market dynamics, influencing how technologies are adopted. Additionally, emerging technologies continue to influence manufacturing practices, offering varied approaches and potentially reshaping market strategies. It’s essential to navigate these complexities with informed decision-making and an awareness of regional and technological landscapes.

Strategic Reflections and Industry Implications

Lasting implications of these trends highlight continuous manufacturing’s critical role in shaping pharmaceutical production’s future landscape. This method promises numerous benefits, including increased productivity and streamlined manufacturing processes. Yet, it also demands changes in mindset, training, and a willingness to adopt new technologies. The shift requires concerted efforts from industry stakeholders to overcome financial and operational hurdles, positioning themselves to fully leverage the potential of continuous manufacturing. Adopting these practices may well define the industry’s trajectory over the coming years.