A quiet but monumental shift is reshaping the foundations of the pharmaceutical industry, driven by a convergence of unprecedented demand for new therapies and the fragile realities of a globally interconnected supply chain. Eli Lilly and Company is at the forefront of this transformation, launching a historic investment campaign to expand its manufacturing capabilities, with a particular focus on fortifying its presence on American soil. This multi-billion-dollar initiative is more than just a series of construction projects; it represents a strategic pivot aimed at ensuring a stable supply of life-changing medicines for patients worldwide while navigating an increasingly complex geopolitical landscape. The core of this strategy is a direct response to the explosive demand for a new class of treatments, particularly in the obesity and diabetes sectors, which has strained existing production lines to their limits and highlighted the critical need for greater capacity and resilience.

From Prescription to Production Meeting the Demand for a New Generation of Medicines

The journey from a successful clinical trial to a medicine available at the pharmacy is a complex logistical marathon, and the recent surge in demand for GLP-1 agonists for diabetes and weight loss has turned it into a full-scale sprint. The immense popularity of these drugs has created a global phenomenon, leading to intermittent shortages and underscoring the gap between existing manufacturing capacity and patient needs. Meeting this demand requires not just assembling finished products but also securing a vast and intricate supply chain for active pharmaceutical ingredients (APIs), the core components of any drug.

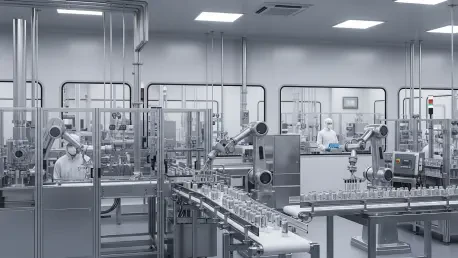

This production challenge is compounded by the advanced nature of the medicines themselves. Modern injectable therapies, such as those being developed for obesity and autoimmune diseases, require sterile manufacturing environments, specialized delivery devices, and a highly skilled workforce proficient in cutting-edge biotechnology. Building facilities capable of producing these complex biologics at scale is a capital-intensive, multi-year endeavor. Consequently, Eli Lilly’s investment is a calculated, long-term commitment to build the infrastructure necessary to support not only its current blockbuster drugs but also a pipeline of next-generation therapies.

The High Stakes of the Modern Supply Chain

The COVID-19 pandemic served as a stark reminder of the vulnerabilities inherent in a globalized supply chain, where disruptions in one part of the world can have cascading effects on the availability of essential goods, including medicines. This post-pandemic reality has prompted a strategic reassessment across the pharmaceutical industry, with a renewed emphasis on diversifying manufacturing locations and reducing dependency on single-source suppliers. Companies are now actively seeking to de-risk their operations by bringing critical production processes closer to home, a strategy known as onshoring or reshoring.

This shift is amplified by significant geopolitical headwinds and economic volatility. The threat of tariffs on imported APIs, raw materials, and laboratory equipment from key manufacturing hubs presents a tangible financial risk. By investing heavily in domestic production, pharmaceutical giants like Eli Lilly are creating a strategic hedge against unpredictable international trade policies and political tensions. This move allows for greater control over the production process, shortens supply lines for the U.S. market, and insulates operations from the kind of global shocks that have become increasingly common.

A Coast to Coast Manufacturing Overhaul

At the heart of Eli Lilly’s domestic expansion is a plan to construct a $3.5 billion state-of-the-art facility in Pennsylvania’s Lehigh Valley. Slated to become operational by 2031, this site will be dedicated to producing injectable medicines and delivery devices, including the company’s promising investigational obesity therapy, retatrutide. The facility is designed to be a model of modern pharmaceutical manufacturing, integrating artificial intelligence, advanced data analytics, and robotics to optimize efficiency and quality. Its establishment is expected to fuel the local economy by creating over 850 high-skilled permanent jobs for scientists, engineers, and technicians.

This Pennsylvania plant is just one piece of a much larger national puzzle. Eli Lilly is simultaneously building a robust backbone for its supply chain with three new API plants. The company has committed a combined $12.5 billion for two facilities in Alabama and Texas, which will focus on producing the key ingredients for oral medicines, including the investigational GLP-1 drug orforglipron. Further east, a $5 billion site in Virginia is under construction to handle complex APIs for innovative cancer and autoimmune therapies. Complementing these new builds is a $1.2 billion investment to modernize an existing facility in Puerto Rico, enhancing its capacity for producing oral solid-dosage medicines.

Inside the Strategy De Risking and Diversification

From an executive viewpoint, this massive capital outlay is a fundamental move to mitigate risk while preserving a global operational footprint. The strategy is not about retreating from international markets but rather about creating a more balanced and resilient network. By increasing domestic capacity, the company ensures it can reliably supply the large U.S. market, which remains the world’s most significant, while still leveraging its global facilities to serve patients in other regions. This dual approach allows for flexibility, enabling production to be shifted between sites as needed to respond to regional demand spikes or localized disruptions.

Industry analysts view this onshoring push as a savvy maneuver in anticipation of future policy shifts. As governments worldwide, including in the U.S., increasingly prioritize domestic manufacturing for critical sectors, companies with established American facilities stand to benefit from potential incentives and a more favorable regulatory environment. This proactive investment positions Eli Lilly not only to meet current demand but also to align with long-term national health security goals. However, the company’s strategy remains decidedly global. A new $3 billion oral medicine facility in the Netherlands will bolster its European capacity, while a $1 billion investment in Indian contract manufacturing further diversifies its production partnerships, demonstrating a sophisticated approach that combines the security of onshoring with the strategic advantages of a globalized network.

The Broader Impact Reshaping the U.S. Pharmaceutical Landscape

The most immediate implication of this manufacturing boom is for patients. A more robust domestic supply chain significantly reduces the likelihood of future drug shortages caused by international shipping delays, trade disputes, or foreign production issues. By having multiple U.S.-based facilities capable of producing both APIs and finished drugs, the system gains redundancy and strength, which should translate into more consistent and reliable access to critical medicines for American consumers.

Beyond patient care, these investments create a powerful economic ripple effect. The creation of thousands of high-paying, skilled jobs in engineering, biotechnology, and advanced manufacturing provides a significant boost to local and regional economies. Furthermore, these facilities foster collaboration with nearby universities and technical colleges, driving STEM workforce development and solidifying the U.S. as a leader in biopharmaceutical innovation. This commitment not only built physical plants but also cultivated the human capital necessary to run them. The strategic decisions made by Eli Lilly established a potential blueprint for the rest of the pharmaceutical industry, signaling a decisive move toward a more secure, resilient, and domestically-focused manufacturing future.