The silent and often invisible loss of energy from industrial pipes, ducts, and equipment represents one of the most significant yet addressable challenges to global sustainability and operational profitability. Within this context, the technical insulation market has emerged as a critical battleground for efficiency, providing specialized materials engineered to control heat transfer, prevent condensation, and enhance safety across a vast spectrum of commercial and industrial environments. This sector is no longer just about wrapping pipes; it is a fundamental enabler of the green transition, a key to reducing industrial carbon footprints, and a strategic investment for businesses aiming to thrive in an era of volatile energy costs and stringent environmental regulations. As industries from power generation to pharmaceuticals push the boundaries of operational performance, the demand for advanced insulation solutions is intensifying, transforming it into a cornerstone of modern infrastructure development and a clear indicator of a worldwide shift toward more sustainable practices.

Financial Projections and Market Trajectory

The global technical insulation market is demonstrating a robust and sustained growth trajectory, reflecting its escalating importance in the global economy. Industry analyses indicate the market is set to expand significantly, with a valuation projected to climb from approximately USD 48.62 billion in 2026 to an impressive USD 69.94 billion by 2035. This steady ascent corresponds to a healthy Compound Annual Growth Rate (CAGR) of 4.12% throughout the forecast period. Such financial momentum is not merely a reflection of increased production but a powerful signal of a broader strategic shift within industries. Companies are increasingly viewing high-performance insulation not as a discretionary expense but as an essential long-term investment. This outlook is anchored in the quantifiable returns that insulation provides, including direct reductions in energy consumption, lower operational costs, and enhanced resilience of critical infrastructure, making it a pivotal component for future-proofing industrial operations against economic and environmental pressures.

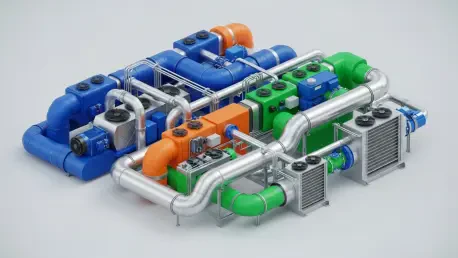

The underlying strength of these market projections is rooted in the indispensable role technical insulation plays in optimizing the performance of essential industrial and commercial systems. These specialized solutions are applied to a wide array of critical infrastructure, including complex piping networks, massive storage tanks, high-temperature boilers, and sophisticated HVAC systems. The applications span vital sectors such as oil and gas, power generation, chemical processing, and the rapidly expanding district energy networks that provide heating and cooling to urban centers. The compelling return on investment is a major factor, as effective insulation directly mitigates thermal losses, thereby reducing fuel consumption and lowering long-term operational expenditures. Furthermore, proper insulation helps prevent costly issues like corrosion under insulation (CUI), extends the functional lifespan of equipment, and improves workplace safety, all of which contribute to a more efficient, reliable, and profitable operation.

Key Catalysts for Market Expansion

A primary force propelling the technical insulation market forward is the intensified global focus on energy efficiency and sustainability, which has become a central pillar of both governmental policy and corporate strategy worldwide. In response to the urgent need to combat climate change and curtail greenhouse gas emissions, regulatory bodies across Europe, North America, and parts of Asia have enacted increasingly stringent mandates for thermal performance in both new and existing infrastructure. These regulations create a direct and sustained demand for advanced insulation materials that can meet or exceed these new standards. Simultaneously, corporations are under mounting pressure from investors and consumers to adopt more sustainable practices and reduce their carbon footprints. Technical insulation offers a tangible and highly effective means to achieve these goals, positioning it as a cornerstone of corporate environmental, social, and governance (ESG) initiatives.

Complementing the push for sustainability, the market is also being significantly driven by the relentless pace of industrialization and infrastructure development, particularly in emerging economies. The ongoing expansion of core industries—including petrochemicals, power generation, and general manufacturing—necessitates the construction of new facilities that require extensive insulation for pipelines, reactors, and processing equipment to ensure optimal efficiency and safety from day one. In parallel, massive public and private investments are being made in large-scale infrastructure projects, most notably the development of district heating and cooling networks in densely populated urban areas. These systems, which rely on vast networks of insulated pipes to transport thermal energy efficiently, represent a major and growing source of demand. This synergy between industrial growth and modern infrastructure upgrades creates a powerful and continuous catalyst for market expansion on a global scale.

Overcoming Market Restraints and Hurdles

Despite a positive growth forecast, the technical insulation market is not without its challenges, chief among them being the high initial investment required for both materials and professional installation. The upfront costs associated with high-performance insulation systems can be substantial, acting as a significant deterrent for companies operating in cost-sensitive industries or in developing regions where immediate capital expenditure is often prioritized over long-term operational savings. This economic barrier can lead to underinvestment or the selection of cheaper, less effective insulation solutions, which ultimately compromises energy efficiency and fails to deliver the full financial and environmental benefits. Moreover, the market is highly susceptible to the price volatility of key raw materials, such as petrochemicals for foams and mineral feedstocks for wools. These fluctuations can directly impact manufacturers’ production costs, creating price instability for end-users and squeezing profit margins throughout the supply chain.

Beyond the economic pressures, the market faces significant hurdles related to workforce skills and market awareness. The ultimate performance of any technical insulation system is heavily dependent on the quality of its installation; even the most advanced materials will fail to perform as specified if installed improperly. A widespread shortage of properly trained and certified installers in many regions poses a critical threat to the industry’s integrity, leading to issues like thermal bridging and moisture ingress that can severely degrade system efficiency and cause long-term damage. Compounding this issue is a persistent lack of awareness in some emerging economies regarding the profound long-term benefits of investing in high-quality technical insulation. This knowledge gap can slow market penetration and hinder the adoption of best practices, underscoring the need for greater industry education and workforce development initiatives to unlock the market’s full potential globally.

Innovative Trends Shaping the Industry

The technical insulation industry is undergoing a significant transformation driven by technological innovation and evolving customer priorities. A clear and dominant trend is the shift toward high-performance materials that deliver superior thermal resistance with reduced thickness and weight. Advanced products like aerogels, while still a premium niche, exemplify this push for maximum efficiency in a minimal footprint, which is critical for space-constrained applications. In parallel, sustainability has become a pivotal purchasing criterion, fueling the development of environmentally friendly insulation products. This includes materials with high recycled content, those that are fully recyclable at the end of their life, and those manufactured with low-emission processes. This movement aligns with the principles of a circular economy and meets the growing demand from corporations looking to build more sustainable supply chains and reduce the environmental impact of their operations.

Another key trend reshaping the market is the increasing adoption of prefabricated and modular insulation systems. These factory-engineered solutions offer numerous advantages over traditional on-site fabrication, including accelerated project timelines, reduced on-site labor costs, and a higher degree of quality control and consistency. They are particularly beneficial for large-scale industrial projects and the construction of extensive district energy networks where speed and reliability are paramount. Furthermore, the market is seeing a greater emphasis on the ancillary properties of insulation beyond its primary thermal function. Characteristics such as fire resistance, acoustic dampening, and moisture management are becoming increasingly critical selection criteria. This is especially true for applications in densely populated industrial plants, commercial high-rises, and critical urban infrastructure, where enhancing safety and occupant comfort are just as important as achieving energy efficiency.

Market Segmentation and Regional Dynamics

The technical insulation market is highly diverse, segmented by material, product type, and end-use industry to serve a wide range of specific application needs. By material type, mineral wool, which includes both stone wool and glass wool, continues to dominate the market. Its widespread adoption is due to an excellent balance of cost-effectiveness, high-temperature resistance, inherent non-combustibility, and versatile applicability across numerous sectors. Elastomeric foam is another major segment, highly valued for its flexibility and superior moisture resistance, making it the ideal choice for refrigeration, plumbing, and HVAC applications where condensation control is critical. Other specialized materials, such as polyurethane (PU), polyisocyanurate (PIR), and phenolic foams, offer distinct performance characteristics tailored for specific temperature ranges. In terms of product type, pipe insulation represents the largest segment, driven by its extensive use in industrial processing plants, energy transportation pipelines, and district heating and cooling systems.

Geographically, the market exhibits distinct regional characteristics and growth patterns. Europe currently stands as the largest market for technical insulation, a position supported by a robust regulatory framework that strongly promotes energy efficiency, the presence of extensive and well-established district heating infrastructure, and high levels of environmental awareness among both corporations and the general public. North America represents a mature but steadily growing market, where demand is largely driven by the modernization of aging industrial facilities, critical infrastructure upgrades, and significant investments in new energy sectors like LNG terminals and data centers. The Asia-Pacific region, however, is projected to be the fastest-growing market over the next decade. This rapid expansion is fueled by unprecedented industrialization, the construction of new power generation capacity to meet rising energy demand, and massive government-led infrastructure projects across key nations like China, India, and Japan.

A Competitive Landscape and Future Outlook

The evolution of the technical insulation market has been defined by a strategic focus on innovation and global expansion, led by a moderately consolidated group of key industry players. Companies such as Saint-Gobain, Rockwool International, and Owens Corning established their market leadership through heavy investment in research and development, which yielded advanced materials with improved thermal efficiency, enhanced durability, and stronger environmental profiles. Their success was built not only on product performance but also on forging strategic partnerships and expanding their geographic footprint to capitalize on regional industrial growth. This competitive environment fostered a cycle of continuous improvement, pushing the entire industry toward higher standards of quality and sustainability. As global demands for decarbonization and operational efficiency grew, these companies positioned technical insulation as an indispensable solution, solidifying its role in modern industry. The market’s trajectory was thus set, underpinned by the non-negotiable need for a more sustainable and energy-efficient global economy.