Manufacturing businesses today thrive by adopting diverse strategies that align with their unique market niches, operational capabilities, and technological advancements. This article takes a deep dive into how three distinct manufacturing companies—Brunner Fabrication, OSH Cut, and Flight Fabrication—leverage specialized business models and cutting-edge technology to drive success while addressing varying market needs.

Introducing the Companies

Brunner Fabrication: Mastering High-Volume Production

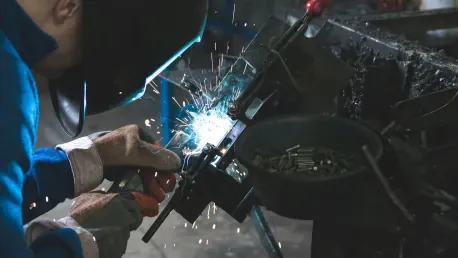

Brunner Fabrication stands out with its focus on high-volume production. By utilizing advanced machinery like a 24-kW fiber laser, Brunner Fabrication excels in producing large quantities of products at lower costs, taking full advantage of economies of scale. This approach allows the company to negotiate lower material prices, further enhancing their competitive edge. This strategy is coupled with a lean organizational structure, maintaining a small but highly efficient team of six employees.

To ensure operational efficiency, Brunner Fabrication avoids taking on small jobs that could disrupt their streamlined processes. By maintaining a keen focus on high-output production, they minimize overhead and maximize revenue, demonstrating the efficacy of a focused high-volume strategy. The ability to produce vast quantities of product at a lower cost without sacrificing quality underscores how specialized technology can significantly bolster an organization’s operational framework.

OSH Cut: Specializing in High-Mix, Low-Volume Production

OSH Cut represents a different end of the spectrum by specializing in high-mix, low-volume production. The company employs automation across various stages, from quoting and inventory management to purchasing and production planning. This technological integration enables OSH Cut to handle thousands of unique part numbers weekly, offering rapid turnarounds for small-batch orders. Their process is tailored to manage a diverse range of customer needs, ensuring that flexibility does not compromise efficiency.

The complexity of OSH Cut’s operations is managed by a more intricate organizational structure comprising around 50 employees, including a dedicated software development team. This structure ensures that even the smallest orders are processed efficiently, delivering a high level of customer convenience and satisfaction. By using advanced software to manage and adapt to complex production demands, OSH Cut demonstrates the importance of investing in technology to handle high-mix, low-volume processes seamlessly.

Flight Fabrication: Bespoke Architecture and Construction

Flight Fabrication carves a niche in the bespoke architectural market, blending traditional craftsmanship with modern CAD technology. Catering to a clientele seeking unique, high-end construction solutions, Flight Fabrication prioritizes customization and quality over volume. Their business model revolves around personalized customer interactions and the ability to produce detailed, bespoke products that offer high aesthetic and experiential value.

Flight Fabrication’s operations exemplify how merging modern technology with age-old techniques can yield superior, one-of-a-kind products. The focus on client interaction and individualized service ensures that every project meets exacting standards. By emphasizing the uniqueness and high-quality artistry in their offerings, Flight Fabrication not only fosters strong client relationships but also solidifies its position in a niche market where detail and craftsmanship are paramount.

Operational Efficiency through Advanced Technology

Leveraging Cutting-Edge Machinery

Advanced technology plays a crucial role in driving operational efficiency across these companies. Brunner Fabrication’s investment in a powerful 24-kW fiber laser significantly accelerates their production processes, enabling the company to maintain a high output while keeping costs down. This investment illustrates how the right machinery can enhance a company’s core competencies and streamline operations. High-volume manufacturers like Brunner Fabrication benefit immensely from such strategic machinery investments, allowing them to execute large-scale projects more efficiently and cost-effectively.

In contrast, OSH Cut’s reliance on automation highlights the importance of software solutions in managing complex production environments. By automating quoting and inventory management, OSH Cut can handle a diverse range of orders swiftly and accurately, underscoring the versatility required in a high-mix, low-volume production setting. The integration of advanced software solutions allows the company to optimize numerous aspects of its operations, thereby maintaining high levels of productivity and customer satisfaction despite the intricate nature of their business.

Traditional Craftsmanship Enhanced by Modern Tools

Flight Fabrication merges traditional skills with modern CAD technology, proving that even in highly specialized markets, technology can enhance productivity and quality. This blending of old and new allows Flight Fabrication to offer bespoke solutions while maintaining high standards of craftsmanship, catering to niche markets where uniqueness and quality are paramount. The use of CAD technology in the design phase complements traditional construction methods, ensuring precision and enhancing the final product’s aesthetic value.

By integrating modern tools with their artisanal approach, Flight Fabrication successfully addresses the growing demand for personalized and high-quality architectural solutions. This strategy demonstrates how even companies deeply rooted in traditional craftsmanship can benefit from modern technology, leading to enhanced operational efficiency and product quality. The approach taken by Flight Fabrication highlights the versatility that technology offers across different manufacturing paradigms, underscoring its role as a pivotal element in modern production processes.

Market-Specific Strategies

High-Volume Production Focus

Brunner Fabrication’s market-specific strategy revolves around high-volume production. By concentrating on producing large quantities efficiently, the company can offer competitive pricing and quick turnaround times, making them an attractive option for clients needing bulk orders. This focus ensures that Brunner Fabrication can leverage economies of scale, further reducing costs and maximizing profit margins. The company’s ability to execute large orders timely and cost-effectively highlights the advantages of a highly specialized, high-volume production approach in today’s competitive market landscape.

Focusing solely on large-scale jobs enables Brunner Fabrication to streamline its processes, thereby reducing disruptions and enhancing overall productivity. This specialization allows the company to remain agile and responsive, maintaining a steady workflow and consistent quality output. Through this methodology, Brunner Fabrication effectively demonstrates how targeting a specific market segment with a specialized production strategy can yield significant operational and financial benefits.

High-Mix, Low-Volume Production Approach

Conversely, OSH Cut’s market strategy is tailored to customers requiring small-batch, highly customized products. Their strength lies in handling numerous unique part numbers efficiently, offering a level of flexibility and responsiveness that larger, high-volume manufacturers might struggle to match. This strategy aligns well with the needs of businesses seeking rapid, customized solutions without the commitment of large orders. By focusing on high-mix, low-volume production, OSH Cut can cater to a diverse range of customer requirements, ensuring high levels of satisfaction and repeat business.

The ability to quickly adapt to varying customer needs is a testament to OSH Cut’s strategic implementation of advanced software solutions and automation. These technological investments allow the company to maintain operational efficiency, even when dealing with complex and small-batch orders. This approach underscores the potential of aligning market strategies with technological capabilities to create a flexible and highly responsive manufacturing model.

Structural and Organizational Models

Lean and Efficient Organizational Structure

Brunner Fabrication maintains a flat organizational structure, employing a lean team of six to ensure minimal overhead and maximum productivity. This lean approach is essential for high-volume businesses where operational efficiency directly impacts the bottom line. A smaller team requires less management oversight and fosters a more agile and responsive work environment. By minimizing management layers and streamlining decision-making processes, Brunner Fabrication can quickly adjust to market demands and operational challenges.

The lean team structure at Brunner Fabrication not only reduces operational costs but also enhances communication and collaboration among team members. This cohesive working environment supports the company’s high-volume production goals, allowing them to maintain their competitive edge and deliver high-quality products efficiently. The model exemplifies how a streamlined organizational structure can contribute to enhanced operational effectiveness and sustained business growth.

Complex Structures for Complexity Management

In contrast, OSH Cut’s more intricate structure includes a dedicated software development team among its approximately 50 employees. This complexity is necessary to manage the multifaceted demands of high-mix, low-volume production. The software development team plays a crucial role in automating and optimizing various processes, ensuring that the company’s operations can scale and adapt to customer needs without sacrificing efficiency. By investing in a specialized team to handle software and technology needs, OSH Cut can stay at the forefront of technological advancements and maintain its position as a leader in customized production.

The complex organizational structure at OSH Cut enables the company to handle a wide range of customer orders with precision and speed. Each team within the organization contributes to managing different aspects of the production process, ensuring that even the most intricate orders are executed smoothly. This approach highlights the importance of having a robust and adaptable organizational framework when dealing with complex and varied production demands.

Investment in Core Capabilities

Strategic Investments in Technology

Manufacturing businesses today flourish by utilizing a range of strategies tailored to their specific market niches, operational strengths, and technological innovations. This article delves deeply into how three unique manufacturing companies—Brunner Fabrication, OSH Cut, and Flight Fabrication—employ specialized business models and advanced technology to achieve success while catering to diverse market demands.

Brunner Fabrication harnesses its extensive experience and skilled workforce to offer custom solutions that meet the exact specifications of its clients. Their focus on precision and quality has garnered them a loyal customer base, allowing them to excel in a competitive industry.

OSH Cut, on the other hand, emphasizes flexibility and speed. By investing in state-of-the-art machinery and software, they have streamlined their production processes, enabling rapid turnaround times for custom orders. This efficiency has positioned them as a go-to provider for clients who need high-quality products on tight deadlines.

Flight Fabrication combines innovation with expertise in aerospace manufacturing. Leveraging advanced materials and cutting-edge engineering techniques, they produce components that meet stringent industry standards. Their commitment to continuous improvement and technological advancement ensures they remain at the forefront of aerospace manufacturing.

In essence, Brunner Fabrication, OSH Cut, and Flight Fabrication each exemplify how specialized business models, tailored strategies, and technological advancements can drive success in the manufacturing sector.