In a momentous technological leap, CESCO EPC, a prominent figure in the grain storage plant industry, recently inaugurated a highly sophisticated automated sheet metal manufacturing facility in Northern Italy. This new facility signifies a significant advancement in CESCO’s commitment to innovation and precision in sheet metal production. Fitted with state-of-the-art robotics and a fully automatic punching and bending line, the facility is supplied by the esteemed German manufacturer TRUMPF, making sure that CESCO remains on the cutting edge of modern manufacturing practices.

Superior Technology Boosts Production Capacity

Cutting-Edge Robotics and Automation

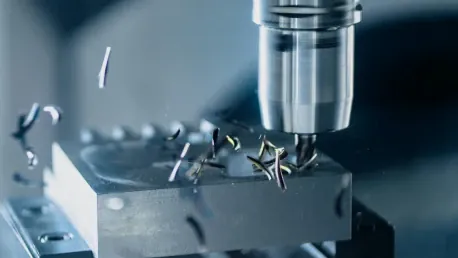

The new automated sheet metal manufacturing facility is a marvel of modern engineering, marked by the integration of cutting-edge robotics and automation technologies. The incorporation of a fully automatic punching and bending line streamlines the production process, ensuring that each piece of sheet metal is produced with pinpoint accuracy. This state-of-the-art technology, provided by TRUMPF, is designed to enhance not only the production capacity but also the quality and precision of the components manufactured. As demand for high-quality, precision-engineered parts continues to rise, this facility is set to play a crucial role in meeting industry needs.

The use of sophisticated loading and unloading systems further amplifies the facility’s efficiency, allowing for seamless production operations. These systems are instrumental in maintaining a consistent flow of materials, ensuring that each phase of the production process is meticulously coordinated. This not only speeds up the manufacturing cycle but also minimizes the risk of human error, thereby guaranteeing a higher quality end product. The automation technology embedded in this facility represents a transformational step towards future-proofing CESCO’s manufacturing capabilities.

Streamlined Processes and Enhanced Precision

One of the standout features of the new facility is its ability to deliver remarkably consistent quality in sheet metal components. With the integration of automated systems, the production process is not only faster but also incredibly precise. This is particularly important for the manufacturing of conveying equipment and square silos, where even minor deviations can significantly impact performance. By leveraging advanced robotics and automation, CESCO ensures that each component is manufactured to exact specifications, thereby enhancing the overall reliability and durability of the final products.

Furthermore, the automated systems facilitate a highly streamlined production process, reducing lead times and improving overall operational efficiency. This is especially beneficial in an industry where timely delivery is critical to maintaining customer satisfaction. The advanced technology in place allows CESCO to respond swiftly to market demands, ensuring that clients receive their orders promptly and without compromise on quality. This commitment to excellence is a testament to CESCO’s dedication to providing superior products and services to its clientele.

Strategic Commitment to Excellence

Investment Reflects Dedication to Quality

Dr. Martino Celeghini, CEO of CESCO EPC, hailed the inauguration of the automated facility as a milestone in the company’s ongoing quest for manufacturing excellence. He emphasized that the significant investment in advanced technology underlines CESCO’s unwavering commitment to delivering top-quality products. By integrating state-of-the-art equipment from TRUMPF, CESCO is taking proactive steps to address the evolving needs of its customers while setting new benchmarks in the industry. This strategic move is reflective of the company’s long-term vision and dedication to maintaining its leadership position in the market.

The collaboration with TRUMPF, a leader in industrial equipment, is a strategic alliance that positions CESCO at the forefront of technological innovation. This partnership is not merely about integrating advanced machinery but also about harnessing the expertise and knowledge that comes with it. TRUMPF’s reputation for producing high-quality industrial equipment ensures that CESCO is equipped with the best tools to achieve manufacturing excellence. This synergy between the two companies is poised to drive significant advancements in production efficiency and product quality, reinforcing CESCO’s reputation as an industry leader.

Faster Production and Improved Service

The inauguration of the new facility is more than just a technological upgrade; it is a strategic initiative aimed at enhancing production speed and service delivery. The advanced automated systems enable faster production cycles, significantly reducing the time it takes to manufacture high-quality sheet metal components. This means that customers can expect quicker turnaround times for their orders, enhancing their overall experience with CESCO. The ability to deliver products more swiftly without compromising on quality is a critical factor in maintaining customer trust and satisfaction.

Moreover, the improved precision and efficiency of the new facility translate into better service for CESCO’s clients. With more reliable and consistent production outputs, customers can have greater confidence in the performance and durability of the products they receive. This, in turn, strengthens the long-term relationships that CESCO has built with its clientele over the years. By continuously investing in advanced technology and optimizing production processes, CESCO reaffirms its commitment to providing unparalleled service and high-quality products in the grain storage plant industry.

Future Prospects and Industry Impact

Aligning with Strategic Goals

The unveiling of CESCO’s new automated sheet metal manufacturing facility aligns perfectly with the company’s strategic goals of increasing production capacity and enhancing precision. This innovation is a direct response to the growing demand for high-quality components in the grain storage plant industry. By integrating advanced robotics and industrial equipment from TRUMPF, CESCO is not only boosting its production capabilities but also setting a new standard for the industry. This move underscores the company’s proactive approach to staying ahead of market trends and meeting the evolving needs of its customers.

CESCO’s continuous investment in technology reflects its long-term vision of achieving manufacturing excellence. This strategic focus ensures that the company remains competitive and capable of addressing future challenges head-on. The new facility is a testament to CESCO’s commitment to innovation and quality, positioning the company as a key player in the industry. By leveraging cutting-edge technology and optimizing production processes, CESCO is well-equipped to meet the increasing demands of the market and deliver superior products to its clients.

Reinforcing Industry Leadership

In a groundbreaking advancement for the grain storage plant sector, CESCO EPC has recently launched a highly advanced automated sheet metal manufacturing facility in Northern Italy. This state-of-the-art plant underscores CESCO’s unwavering dedication to innovation and precision in the sheet metal production arena. The new facility is equipped with the latest robotics technology and features a fully automated punching and bending line, thereby ensuring unparalleled efficiency and accuracy in production. The key supplier for this high-tech machinery is the renowned German manufacturer TRUMPF, a name synonymous with excellence in the field of industrial machinery. By incorporating TRUMPF’s cutting-edge technology, CESCO guarantees that it remains at the forefront of modern manufacturing practices. This strategic move not only enhances CESCO’s operational capabilities but also sets a new benchmark for quality and efficiency in the industry. Through this state-of-the-art facility, CESCO reiterates its commitment to leading the way with innovative solutions and top-tier production standards in the sheet metal manufacturing sector.