As we dive into the cutting-edge world of additive manufacturing, I’m thrilled to chat with Kwame Zaire, a renowned expert in manufacturing with a deep focus on electronics, equipment, and production management. Kwame has established himself as a thought leader in predictive maintenance, quality, and safety, and today, we’re exploring his insights on a groundbreaking development in metal 3D printing. Our conversation centers around a pioneering partnership in the aerospace sector, where advanced metal printing technology is being leveraged to push the boundaries of reusable launch vehicle production. We’ll discuss the intricacies of adopting new systems, the impact of high-precision machinery on design and manufacturing, and the broader implications for the industry’s future.

How did this journey with advanced metal 3D printing technology begin, and what sparked the interest in becoming an early tester for a cutting-edge machine like the MetalFab 420K?

It all started with a desire to stay ahead in the rapidly evolving field of manufacturing, especially in aerospace where precision and speed are paramount. We were already familiar with additive manufacturing and had been using earlier systems, so when the opportunity came to test the MetalFab 420K as a beta partner, it felt like a natural fit. The promise of enhanced productivity and reliability was a big draw, and being an early tester allowed us to shape how this technology could meet our specific needs for complex components.

What were some of the standout factors that convinced you to scale up your investment in this technology after the initial testing phase?

During the beta phase, we saw firsthand how the MetalFab 420K delivered on its promises. The precision and consistency in producing parts for our reusable launch vehicle were exceptional, and it significantly cut down the time from design to finished hardware. That kind of efficiency is a game-changer for us, and it gave us the confidence to invest in multiple units to ramp up our production capacity.

Can you share some of the challenges encountered during the beta testing period, and how you managed to overcome them?

Absolutely, no new technology comes without hurdles. One of the main challenges was integrating the machine into our existing workflow. There were initial hiccups with calibration and ensuring the system could handle the specific materials we use. We worked closely with the development team, running numerous test prints and tweaking settings. Their support was invaluable, and by the end of the six months, we had a setup that was seamless and reliable.

Could you walk us through the process of installing this advanced system at your facility and what that moment signified for your team?

Setting up the MetalFab 420K at our Kent facility was a milestone. It happened in May 2025, and there was a palpable excitement among the team. The installation itself was meticulous—ensuring the environment was right for such a high-precision machine took careful planning. Once it was up and running, it felt like we were stepping into a new era of production. It wasn’t just about the machine; it was about what it represented for our ability to innovate faster.

What types of components were you able to produce during the testing phase, and how did that impact your overall project goals?

We focused on producing intricate parts for our reusable launch vehicle—components that required high accuracy and durability under extreme conditions. Being able to print these directly with the MetalFab 420K meant we could iterate designs much quicker than traditional methods. It aligned perfectly with our goal of accelerating development cycles and getting closer to flight-ready hardware.

How does the precision and reliability of this technology influence your ability to move swiftly from a concept on paper to actual hardware ready for use?

The precision of the MetalFab 420K is a standout feature. When you’re dealing with aerospace components, even a minor deviation can be a dealbreaker. This machine’s consistency meant we could trust the output right from the first print, reducing the need for extensive post-processing. That reliability translates directly into speed—shaving weeks off our timelines and allowing us to test and refine designs in real-time.

In what ways does additive manufacturing fit into your broader design and production strategy?

Additive manufacturing is at the core of how we approach design and production. It allows us to create complex geometries that would be impossible or too costly with traditional methods. It also supports rapid prototyping, so we can test multiple iterations without committing to expensive tooling early on. Strategically, it gives us the flexibility to adapt quickly to design changes or new requirements, which is crucial in a field as dynamic as aerospace.

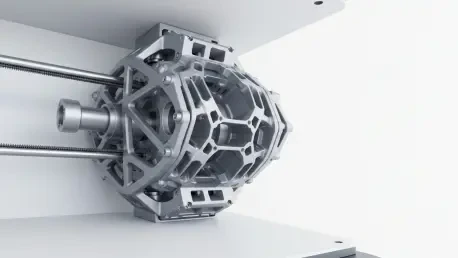

Can you elaborate on how the specific features of this machine, like its powerful laser system, enhance your production process compared to other equipment you’ve worked with?

The MetalFab 420K’s four 1 kW full-field lasers are a significant upgrade. They allow for faster build times without sacrificing detail or quality. Compared to other machines we’ve used, this system can handle larger areas at once, which means we’re producing parts in a fraction of the time. That speed, combined with the accuracy of the lasers, has streamlined our workflow in ways we hadn’t anticipated.

How would you describe the collaboration with the technology provider during the beta program, and what built your trust in their system for full-scale production?

The collaboration was incredibly hands-on and supportive. From day one, their team was committed to ensuring the system worked for our specific applications. They were open to feedback, quick to address issues, and genuinely invested in our success. That level of partnership, along with the performance data we gathered during testing, made it clear their technology was ready for the demands of full-scale production.

What does this significant investment in new machinery signal about your future plans and production ambitions?

This investment is a clear statement of our commitment to scaling up and pushing the boundaries of what’s possible in aerospace manufacturing. It’s about building capacity to meet ambitious production targets and ensuring we can deliver on our vision of reusable launch systems. It signals that we’re not just experimenting—we’re ready to lead with advanced manufacturing as a cornerstone of our growth.

How do you think this kind of technological advancement could influence the aerospace industry, particularly for companies focused on reusable launch systems?

I believe it’s going to be transformative. Reusable launch systems demand high precision and rapid turnaround, and technologies like the MetalFab 420K enable that at scale. For the industry, it means lower costs, faster innovation cycles, and the ability to produce components that were previously unfeasible. It could inspire more companies to adopt additive manufacturing as a primary production method, reshaping how we approach space exploration.

What is your forecast for the future of additive manufacturing in aerospace over the next decade?

I’m very optimistic. Over the next ten years, I expect additive manufacturing to become even more integral to aerospace. We’ll likely see advancements in materials that can withstand even harsher conditions, as well as machines with greater speed and larger build volumes. The technology will drive down costs and open up new possibilities for design, ultimately making space more accessible. I think we’re just at the beginning of what’s possible, and partnerships like ours will pave the way for broader adoption and innovation.