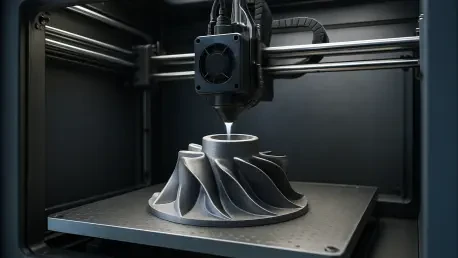

What if a critical part for an offshore drilling rig could be produced on-site in hours instead of waiting weeks for delivery through complex supply chains? In 2025, additive manufacturing (AM), commonly known as 3D printing, is making this a reality for the oil and gas industry, tackling logistical nightmares with unprecedented speed. This technology is not just a novelty; it’s a lifeline for an industry grappling with remote operations and razor-thin margins. As the sector gathers for a landmark summit in Houston this year, the potential of AM to reshape energy operations comes into sharp focus.

The significance of this shift cannot be overstated. With global energy demands climbing and sustainability pressures mounting, oil and gas companies face a dire need for innovative solutions. Additive manufacturing offers a path to cut costs, reduce downtime, and enhance resilience in some of the harshest environments on Earth. Events like the Additive Manufacturing for Oil & Gas Summit, held on October 15-16 in Houston, Texas, are spotlighting how this technology is becoming a cornerstone of operational strategy, driving efficiency and adaptability across the value chain.

Why Additive Manufacturing Is a Game-Changer for Oil & Gas

At its core, additive manufacturing addresses long-standing inefficiencies that have plagued the oil and gas sector for decades. Traditional methods often involve lengthy lead times for parts, especially in upstream operations where delays can cost millions. AM flips this model by enabling on-site production, slashing wait times and logistics costs. Industry reports suggest that companies adopting AM have seen downtime reductions of up to 60% in remote locations, a statistic that underscores its transformative impact.

Beyond speed, the technology aligns seamlessly with the push for digital transformation. By integrating with Industry 4.0 frameworks, AM allows for data-driven design and production, ensuring that components meet exact specifications even in the field. This synergy is not just about keeping rigs running; it’s about building a smarter, more responsive industry capable of meeting modern challenges head-on.

The Critical Need for AM in Today’s Oil & Gas Landscape

The stakes for oil and gas have never been higher, with volatile markets and environmental mandates creating a perfect storm of complexity. Supply chain disruptions, particularly for specialized equipment in isolated areas, often lead to operational halts that bleed revenue. Additive manufacturing steps in as a vital solution, offering the ability to produce complex parts on demand, whether on a North Sea platform or a desert drilling site, minimizing the risk of costly delays.

Moreover, the drive toward sustainability adds another layer of urgency. Traditional manufacturing generates significant waste, whereas AM optimizes material use, cutting scrap by as much as 40%, according to recent studies. This efficiency not only lowers costs but also supports corporate goals for reduced environmental impact, making AM a strategic tool for navigating regulatory and public expectations in 2025 and beyond.

How AM Is Redefining Operations Across the Sector

Additive manufacturing is proving its worth through targeted applications that address specific pain points in oil and gas operations. In upstream activities, rapid prototyping and production of high-value components are minimizing downtime, with some firms reporting repair cycles cut from weeks to days. This capability is a lifeline for drilling sites where every hour of inactivity translates to substantial losses.

In remote environments, AM’s on-demand solutions are equally impactful. Harsh conditions no longer mean logistical gridlock; spare parts can be printed directly at the point of need, reducing dependency on distant warehouses. Additionally, by supporting digital oilfield initiatives, AM enhances operational flexibility through smart manufacturing, while early adopters highlight cost savings and waste reduction as key benefits, with inventory overheads dropping by nearly 30% in pilot projects discussed at industry forums this year.

Insights from Industry Leaders at the Houston Summit

The Additive Manufacturing for Oil & Gas Summit in Houston, hosted by Ascentis Strategies Institute, is a critical platform for understanding AM’s real-world impact. Featuring experts like John Barnes of ExxonMobil, Christopher Saldana from the Department of Energy, and Chelsea Green of BP, moderated by Carlo De Bernardi of ConocoPhillips, the event offers a deep dive into both successes and obstacles. Their collective perspective emphasizes that while AM delivers undeniable advantages, challenges like intellectual property risks and data security in distributed networks remain significant hurdles.

Panel discussions at the summit reveal a shared belief in the power of collaboration. Speakers stress that overcoming barriers to AM adoption requires joint efforts between operators, OEMs, and service providers. Their insights, drawn from hands-on experience, provide a roadmap for navigating complexities, with actionable strategies emerging from sessions designed to bridge theory and practice in this evolving field.

Practical Pathways to Integrate AM into Oil & Gas Operations

Adopting additive manufacturing is a strategic endeavor that demands careful planning, and the Houston Summit agenda lays out clear steps for implementation. Companies must first assess high-impact areas, such as upstream repairs or remote logistics, where AM can deliver immediate results. Investing in tailored equipment and training ensures readiness for rugged environments, while integrating these tools with existing systems maximizes efficiency.

Equally critical is safeguarding data and intellectual property in a distributed AM setup, a concern repeatedly raised by summit speakers. Developing robust security protocols is non-negotiable. Furthermore, leveraging industry platforms like the Houston event for collaboration with peers and OEMs can accelerate pilot projects, while aligning AM with broader Industry 4.0 goals ensures long-term value. With advanced registration closing on August 15, prompt action is essential for organizations aiming to stay ahead of the curve.

Reflecting on a Turning Point for Oil & Gas Innovation

Looking back at the discussions and revelations from the Additive Manufacturing for Oil & Gas Summit in Houston, it became evident that AM had cemented its role as a pivotal force in the industry. The event showcased how this technology tackled entrenched challenges, from slashing downtime to enhancing sustainability, through real-world applications and expert insights. It painted a picture of an industry ready to embrace change despite the hurdles.

Moving forward, the path was clear: companies needed to prioritize strategic investments in AM, focusing on training, security, and partnerships to unlock its full potential. The next steps involved pilot programs and cross-sector collaboration to refine approaches, ensuring that from 2025 to 2027, the technology scaled effectively. As the sector stood at this crossroads, the momentum built in Houston offered a blueprint for resilience and innovation in the years ahead.