China’s textile industry is undergoing a significant transformation driven by the dual forces of digitalization and sustainability. As global demands shift and technological advancements accelerate, the industry is evolving rapidly to maintain its position in the international market. This article delves into the various ways China’s textile sector is embracing digital and green trends to stay competitive.

Digitalization in the Textile Industry

The Rise of Fast Fashion

Fast fashion brands like Shein and Temu are leading the charge in digitalizing the textile industry. They utilize advanced AI and data analytics to analyze consumer preferences and predict trends. This information allows for efficient inventory management and rapid production cycles, significantly reducing the time from design to market. These companies have set new benchmarks for how quickly fashion can be brought to consumers, relying on an agile supply chain and a robust digital infrastructure.

Shein, in particular, has become a paragon of this fast fashion model, using sophisticated algorithms to evaluate which styles are gaining traction and directing production accordingly. The company’s large-scale automated test and re-order (LATR) models ensure their supply chain can quickly adapt to changing consumer tastes. This method also minimizes excess inventory, aligning production closely with actual demand. Temu similarly employs digital tools to streamline its operations, enabling rapid adjustments based on real-time data analytics. This digital-first approach is enabling these companies to thrive in an increasingly competitive global market.

Advanced Manufacturing Technologies

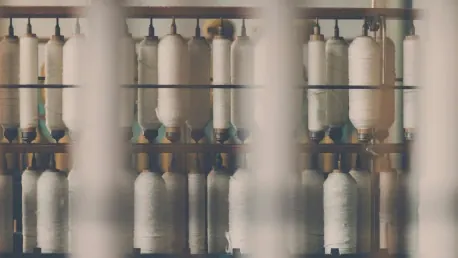

Chinese textile manufacturers are investing heavily in state-of-the-art manufacturing technologies. From automated spinning machines to high-speed weaving looms, these advancements contribute to higher efficiency and lower production costs. Automation reduces the reliance on manual labor, thereby minimizing errors and enhancing the overall quality of the final products. This technology also allows for greater customization in the manufacturing process, catering to specific consumer demands and emerging trends.

The adoption of such advanced technologies is revolutionizing the textile manufacturing landscape in China. Automated machinery not only speeds up production but also elevates accuracy and consistency. For instance, rotor spinning technology has gained prominence due to its efficiency and flexibility. This technique enables the production of yarn at high speeds while maintaining excellent yarn quality. Moreover, advancements in chemical recycling technologies are paving the way for more sustainable production methods. By converting textile waste into high-quality fibers, manufacturers can reduce their environmental footprint and meet the growing demand for eco-friendly products.

Integration of Digital Platforms

Integration of digital platforms across the supply chain is another significant aspect of digitalization in China’s textile industry. These platforms facilitate seamless communication between different stages of production, from raw material procurement to final product delivery. Digital tools like ERP (Enterprise Resource Planning) systems and SCM (Supply Chain Management) software enable real-time monitoring and management of operations. This integration ensures that the entire supply chain is more responsive and adaptable to market changes.

The use of these digital platforms is transforming how textile companies operate on a day-to-day basis. Real-time data tracking improves transparency and allows for more informed decision-making, enhancing the overall efficiency of the supply chain. For instance, digital platforms enable instant communication between suppliers and manufacturers, ensuring timely deliveries and minimizing production delays. Furthermore, the integration of digital platforms supports the automation of routine tasks, freeing up human resources for more strategic roles. As the industry continues to embrace these technologies, the ability to quickly respond to market shifts and consumer demands becomes a critical competitive advantage.

Green Trends in Textile Manufacturing

Sustainable Materials and Recycling

China’s textile manufacturers are increasingly focusing on sustainable materials and recycling processes. The integration of recycled fibers and eco-friendly dyes is becoming more common, driven by both global sustainability goals and consumer demand for environmentally responsible products. Companies are investing in chemical recycling technologies that can convert textile waste into new, high-quality fibers. This not only reduces waste but also conserves resources that would otherwise be used in producing virgin materials.

To meet these sustainability goals, companies are also exploring innovative materials such as bio-based fibers and organic cotton. These materials have a lower environmental impact compared to conventional fibers, contributing to a more sustainable supply chain. Additionally, initiatives like closed-loop recycling systems are gaining traction, where post-consumer textile waste is recycled back into new products. This approach not only conserves resources but also reduces the environmental burden of textile waste. As these practices become more widespread, China’s textile industry is positioning itself as a leader in sustainable manufacturing, aligning with international standards and consumer expectations.

Energy-Efficient Technologies

Adopting energy-efficient technologies is a crucial part of China’s strategy to make its textile industry more sustainable. Modern machinery and production processes are designed to consume less energy and produce lower emissions. Innovations like low-temperature dyeing and waterless printing are gaining traction, helping to minimize the environmental impact of textile manufacturing. These technologies not only align with global standards for sustainability but also offer cost savings through reduced energy consumption.

Energy-efficient technologies are becoming a key focus for manufacturers looking to enhance both their sustainability and profitability. For example, energy-efficient dyeing machines require significantly less water and chemicals, reducing waste and lowering operational costs. Similarly, advances in digital printing technology allow for more precise application of dyes and finishes, reducing material usage and waste. By adopting these technologies, textile manufacturers can achieve a more sustainable production process, meet regulatory requirements, and appeal to eco-conscious consumers. As the industry continues to innovate, the integration of energy-efficient technologies will play a pivotal role in its transformation.

Regulatory Compliance and Certifications

To meet international standards and appeal to environmentally conscious consumers, many Chinese textile companies are seeking certifications such as OEKO-TEX and GOTS (Global Organic Textile Standard). Compliance with these certifications indicates a commitment to high environmental and social standards, enhancing the reputation of Chinese textiles in global markets. Companies are also collaborating with international organizations to stay updated with evolving regulations and best practices.

Certifications serve as a testament to the industry’s dedication to sustainability and social responsibility. Achieving these certifications requires rigorous adherence to criteria concerning material safety, production processes, and environmental impact. By obtaining such certifications, companies not only bolster their credibility but also tap into new market opportunities where sustainability is a key purchasing criterion. Collaborations with international bodies further ensure that Chinese textile manufacturers remain compliant with global standards, enhancing their competitive edge in an increasingly eco-conscious market landscape. These efforts underscore the industry’s proactive approach to sustainability and regulatory compliance.

Market Dynamics and Consumer Behavior

Changing Consumer Preferences

The digital age has brought about a notable shift in consumer behavior, particularly in the fashion segment. Consumers are now more informed and discerning, thanks to the abundance of information available online. They seek not only trendy and affordable clothing but also products that align with their values, such as sustainability. This shift has prompted traditional brands and retail channels to adapt their business models to stay relevant. Companies are employing extensive digital marketing strategies and leveraging social media to engage with consumers directly, creating a more personalized shopping experience.

The rise of e-commerce platforms has further accelerated this shift, providing consumers with a plethora of options at their fingertips. Brands are now using social media influencers and targeted advertising to reach their audience more effectively. Consumer engagement has also become more interactive, with brands using platforms like Instagram and TikTok to showcase their products and gather feedback. This level of direct interaction allows companies to tailor their offerings to better match consumer preferences. As a result, traditional brick-and-mortar stores are transforming into experiential spaces where consumers can interact with brands in person, complementing the online shopping experience.

Competitive Strategies

To stay ahead in the competitive landscape, Chinese textile companies are adopting various strategies. These include diversifying their product offerings, investing in branding, and focusing on quality over quantity. By differentiating themselves through unique and high-quality products, companies can attract a broader customer base and build long-term brand loyalty. Collaborations with international designers and influencers are also becoming a popular strategy to expand market reach and enhance brand image.

Branding has become a critical component of these strategies, enabling companies to establish a distinct market presence. Investment in branding helps build a strong brand identity, which resonates with consumers and creates a loyal customer base. Companies are also exploring niche markets and premium segments where quality and exclusivity are highly valued. By offering a diverse range of high-quality products, companies can cater to various consumer tastes and preferences. Collaborations with well-known designers and influencers not only boost brand visibility but also add a seal of approval, attracting even more customers. This multi-faceted approach ensures that Chinese textile companies remain competitive and continue to thrive in a dynamic market environment.

Impact of Global Legislation

Legislation from major markets like the US and EU plays a significant role in shaping the dynamics of China’s textile industry. Tariffs, trade agreements, and anti-dumping laws can either hinder or facilitate the flow of goods. In response to these challenges, Chinese companies are exploring new markets and strengthening their domestic presence. They are also investing in legal and compliance teams to navigate complex international regulations and ensure uninterrupted market access.

For instance, recent changes in trade policies have prompted Chinese companies to diversify their export markets, reducing dependency on any single region. By targeting emerging markets in Asia, Africa, and South America, companies are mitigating risks associated with geopolitical tensions and protectionist measures. Strengthening domestic operations also helps insulate businesses from external shocks, ensuring stability and growth. Legal and compliance teams are essential in this context, providing expertise in international laws and regulations to ensure seamless market entry and sustained operations. These proactive measures demonstrate the industry’s resilience and adaptability in facing global legislative challenges.

Technological Investments and Innovations

Digital Networks and Industry 4.0

The concept of Industry 4.0, characterized by the integration of digital networks and smart manufacturing, is becoming increasingly prevalent in China’s textile sector. Factories are incorporating IoT (Internet of Things) devices and sensors to monitor and optimize production processes in real-time. This digital transformation enhances operational efficiency, reduces downtime, and enables predictive maintenance. By leveraging big data and machine learning, businesses can make more informed decisions and improve overall productivity.

Industry 4.0 technologies are transforming traditional manufacturing processes, making them more sophisticated and integrated. IoT devices collect data from various stages of production, providing valuable insights that can be used to optimize operations. Predictive maintenance, powered by machine learning algorithms, reduces the likelihood of equipment failure and minimizes downtime. This ensures a smoother production process and maximizes output. Furthermore, big data analytics offers deeper insights into market trends and consumer behavior, enabling companies to make strategic decisions that align with market demands. The adoption of these technologies is driving a paradigm shift in the textile industry, setting the stage for continued innovation and growth.

Developments in Rotor Spinning Technology

China’s textile industry is undergoing a noteworthy transformation, largely fueled by the dual dynamics of digitalization and sustainability. In response to shifting global demands and rapid technological advancements, the sector is evolving quickly to maintain its competitive edge on the international stage.

Digitalization is playing a crucial role in this transformation, with many companies adopting advanced technologies such as artificial intelligence, big data, and automation. These technologies not only streamline operations but also enhance product quality and improve supply chain efficiency. For example, using AI for predictive maintenance can minimize downtime, while big data analytics can help in demand forecasting, allowing companies to better meet customer needs and reduce waste.

Sustainability is another key focus. The industry is increasingly committed to eco-friendly practices, from using organic and recycled materials to implementing energy-efficient processes. Many companies are also turning to sustainable manufacturing methods like waterless dyeing and low-impact production techniques to reduce their environmental footprint. These efforts align with global trends advocating for more responsible and ethical production practices.

In summary, China’s textile sector is rapidly adapting to the demands of a modern, tech-savvy market while also prioritizing sustainability. By embracing these trends, the industry aims to lead in both innovation and environmental stewardship, securing its place in the global market for years to come.