The Race for a New Generation of Medicines

The biopharmaceutical landscape is in the midst of a revolution, driven by the unprecedented potential of gene therapies and mRNA vaccines. These advanced therapies promise to treat, and even cure, diseases once considered intractable. However, their development and commercialization hinge on a critical, often overlooked, manufacturing challenge: the production of vast quantities of high-purity plasmid DNA. As the foundational template for these next-generation medicines, plasmid DNA is in higher demand than ever, creating a significant bottleneck that can stall progress. In response, Thermo Fisher Scientific has introduced a breakthrough solution designed to shatter this barrier. This article will explore how the company’s new biomanufacturing media is engineered to double plasmid DNA yields, analyzing the technology, its broader implications, and its central role in Thermo Fisher’s strategy to power the future of medicine.

The Plasmid Predicament: Why Traditional Manufacturing Falls Short

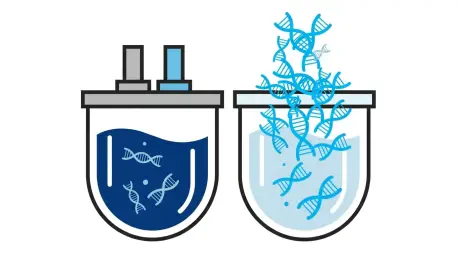

To understand the impact of Thermo Fisher’s innovation, it is essential to grasp the historical context of plasmid production. For decades, the workhorse of this process has been the bacterium E. coli, grown in large-scale fermenters. The culture media used to nourish these bacteria has traditionally been complex, often containing undefined, animal-derived components like yeast extract or peptones. While effective to a point, this approach presents significant drawbacks. The inherent variability of these complex ingredients leads to inconsistent batch-to-batch performance, complicating efforts to scale production reliably. Furthermore, the use of animal-origin components introduces potential safety risks and creates a more arduous, complex regulatory pathway for new therapies. These limitations have long capped a ceiling on both the efficiency and scalability of plasmid DNA manufacturing, a ceiling the industry must now break to meet surging clinical and commercial demand.

A Breakthrough in Bioprocessing Technology

A Chemically Defined Solution: Unpacking the New Gibco Media System

At the heart of Thermo Fisher’s strategy is the launch of its Gibco Bacto CD Supreme FPM Plus and Gibco Bacto CD Supreme Feed (2X). The key innovation lies in their formulation: they are “chemically defined” (CD), meaning every single component is known and quantified. This eliminates the guesswork and variability associated with traditional complex media. Being hydrolysate-free and animal origin–free, these products directly address the core challenges of regulatory compliance and supply chain security that have plagued manufacturers. By providing E. coli with a precisely optimized and consistent nutritional environment, this system creates the ideal conditions for robust growth and, most importantly, maximized plasmid replication. The result is a dramatic and quantifiable improvement, with Thermo Fisher reporting that the new media system can boost plasmid DNA yields by up to 120% compared to conventional methods.

From Lab to Market: Streamlining Scalability and Regulatory Approval

A significant yield increase is a headline-grabbing achievement, but the deeper value of this chemically defined system lies in its ability to streamline the entire production workflow. The enhanced batch-to-batch consistency ensures that processes developed in a small-scale laboratory setting can be reliably reproduced at large commercial volumes, a concept known as seamless scalability. This predictability de-risks the costly and time-consuming process of scaling up manufacturing. For biopharmaceutical companies, this means a faster and more efficient path from clinical trials to market launch. By removing animal-derived components, the media also simplifies the regulatory submission process, helping drug developers meet the stringent safety and purity standards required by agencies like the FDA and EMA. This combination of higher yields and a smoother operational pathway provides a powerful competitive advantage in the fast-moving advanced therapies sector.

More Than MediA Global Strategy for Bioprocessing Dominance

The launch of the new Gibco media is not an isolated event but a calculated move within Thermo Fisher’s broader corporate vision. The company is executing a comprehensive global strategy to solidify its position as an end-to-end partner for the biopharmaceutical industry. This is evidenced by a pattern of significant international investment, including the establishment of a new bioprocess design center in India, facility upgrades in Korea and Singapore, and the launch of an Advanced Therapies Collaboration Center in Philadelphia. This center, in particular, is designed to foster innovation by giving startups and emerging biotechs access to Thermo Fisher’s technology and expertise. By providing both the cutting-edge consumables—like the new CD media—and the global infrastructure to support their use, Thermo Fisher is building an integrated ecosystem designed to accelerate the development of modern biologics for clients of all sizes.

The Future of Biomanufacturing: Setting a New Industry Standard

Thermo Fisher’s advancement signals a pivotal shift in biomanufacturing, with far-reaching implications for the future. The success of this chemically defined system for plasmid DNA production is likely to accelerate a wider industry transition away from complex media for all types of biologics. As consistency and regulatory simplicity become non-negotiable, CD media will evolve from a premium option to the industry standard. This drive for efficiency could also have a profound economic impact; by increasing yields so dramatically, innovations like this may help lower the per-dose manufacturing cost of gene therapies and mRNA vaccines. This, in turn, could improve their accessibility to patients worldwide. The launch sets a new benchmark for performance, challenging competitors and inspiring further innovation in bioprocess optimization to keep pace with the rapid evolution of advanced therapeutics.

Strategic Imperatives for the Modern Biopharma Company

The analysis of Thermo Fisher’s new offerings provides clear takeaways for stakeholders across the industry. For established biopharmaceutical companies and contract development and manufacturing organizations (CDMOs), the primary directive is to evaluate and adopt advanced, chemically defined systems to de-risk manufacturing and maximize productivity. In a competitive market, relying on legacy processes is no longer a viable strategy. For early-stage researchers and startups, the key is to leverage the integrated support systems being built by industry leaders, such as Thermo Fisher’s Collaboration Centers, to accelerate development timelines and avoid common scale-up pitfalls. The overarching lesson is that process optimization is not a final step but a foundational element of a successful therapeutic program, critical for achieving speed, quality, and scale.

Enabling the Future of Medicine, One Plasmid at a Time

In conclusion, Thermo Fisher Scientific’s new Gibco CD media represents far more than just an incremental improvement; it is a targeted technological solution to one of the most significant constraints in modern medicine. By doubling plasmid DNA yields through a chemically defined, scalable, and regulatory-friendly platform, the company is directly addressing the needs of the burgeoning gene therapy and mRNA vaccine markets. This product launch, when viewed in the context of the company’s strategic global investments, underscores a clear commitment to enabling the entire biopharmaceutical value chain. Ultimately, foundational advancements in manufacturing like this are the critical enablers that will allow the revolutionary promise of advanced therapies to become a widespread clinical reality.