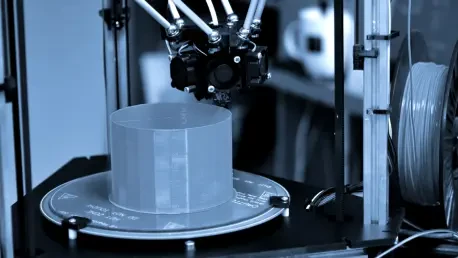

LaserTool’s strategic acquisition of advanced additive manufacturing technology marks an exciting turning point in the sector. By investing in Nikon’s SLM Solutions Powder Bed Fusion by Laser Beam (PBF-LB) machine, the company not only escalates its production capabilities but also aligns with the future of manufacturing methods. This analysis explores how this investment positions LaserTool as an industry leader and the broader implications for manufacturing trends.

Industry Standpoint: Contextualizing the Shift

The investment by LaserTool reflects crucial advancements and prevailing trends in the manufacturing industry. Traditionally dominated by conventional machining processes, manufacturing now embraces additive techniques due to their efficiency and precision. LaserTool’s decision to adopt PBF-LB technology exemplifies a growing industry-wide recognition of additive manufacturing’s potential to revolutionize production. By facilitating the creation of intricate geometries with reduced material waste, such technologies represent a decisive step toward more sustainable and agile manufacturing solutions.

Emerging Trends and Technological Integration

Precision as a Core Advantage

Precision manufacturing has become ever more critical, as industries demand components with increasingly complex designs. The PBF-LB machine, renowned for its unparalleled accuracy, promises to enhance LaserTool’s capability in this domain. The shift to such high-tech machinery suggests a tactical move to overcome traditional production limitations, thus broadening the company’s scope for customization and quality improvement. As firms across industries embrace similar technologies, they report significant gains in efficiency and product quality, underscoring the importance of precision technology adoption.

Widespread Adoption of Additive Methods

The embrace of additive manufacturing signals a paradigm shift, with industries poised to redefine production processes. The integration of advanced technology by companies like LaserTool symbolically leads to disruptive innovation trends that resonate across manufacturing landscapes. The commitment to additive methods is often driven by increasing demands for sustainable production, highlighting the role such technologies play in achieving economic efficiencies. As LaserTool advances in this direction, it sets new precedents in industry standards and customer offerings.

Nuances of Global Market Dynamics

LaserTool’s venture into geographically diverse markets requires adaptive strategies that consider regional complexities. Each geographic area presents unique challenges and opportunities, suggesting that LaserTool’s success might depend on tailored approaches to local market demands. Understanding regional specificities can mitigate risks and uncover hidden advantages, enabling effective adaptation of global strategies. Knowledge of local manufacturing ecosystems offers insights that contribute to maximizing the positive impact of LaserTool’s investment.

Forecasting the Future Trajectory of Additive Manufacturing

Additive manufacturing is advancing rapidly, integrating with digital technology to improve automation and precision. Analysts predict continued refinement and increased adoption of techniques like PBF-LB across multiple sectors. Regulatory frameworks are expected to evolve, facilitating safer and more efficient global practices. LaserTool’s positioning as a technological pioneer seamlessly aligns with industry transformations, thus heralding broader economic innovations and competitive advantages in manufacturing.

Strategic Insights and Recommendations

The lessons learned from LaserTool’s investment provide key strategic guidance for companies navigating technological adoption. Enterprises are encouraged to prioritize investment in advanced equipment and cultivate a culture of ongoing learning. Aligning technological advancements with evolving customer demands can sustain competitiveness and bolster performance. Understanding these strategic recommendations can enable businesses to effectively harness manufacturing innovations, achieving substantive operational benefits.

Reflecting on the Findings

In retrospect, LaserTool’s investment in the Nikon SLM Solutions PBF-LB machine became a catalyst for innovation in manufacturing. This strategic move was a testament to the power of embracing cutting-edge technology to secure a competitive position in evolving industry landscapes. While technological adoption presented challenges, proactive leadership and strategic foresight paved the way for transformation. Looking ahead, companies harnessing similar strategies will likely pioneer future practices in manufacturing and position themselves at the forefront of industry evolution.