Manufacturing has long been a cornerstone of North Carolina’s economy. From the 19th century, when manufacturing began to eclipse farming, to the present day, the industry has undergone significant transformations. Today, North Carolina stands at a crossroads, balancing its rich historical legacy with a future poised for technological integration and modernization.

Historical Context and Significance

The Rise of Manufacturing in North Carolina

In the 19th century, manufacturing became the dominant economic sector in North Carolina, surpassing agriculture. The state’s economy was driven by the “big three” industries—tobacco, textiles, and furniture manufacturing. These industries were closely linked to the state’s agricultural outputs, creating a seamless connection between farming and manufacturing. Raw materials such as tobacco, cotton, and wood were directly used in the state’s manufacturing sectors, making North Carolina a manufacturing powerhouse.

This seamless connection allowed for the growth of robust manufacturing hubs throughout the state. Towns and cities flourished, offering employment opportunities that drew workers from rural and urban areas alike. Factories sprang up amid sprawling farmlands, turning North Carolina into a major player in national manufacturing. By integrating agriculture and manufacturing so seamlessly, North Carolina created an economy that was resistant to fluctuations in individual sectors. As demand for manufactured goods grew both domestically and internationally, North Carolina’s industries thrived and became symbols of innovation and economic prowess.

The Decline of Traditional Manufacturing

By the late 20th century, the dominance of traditional manufacturing began to wane. International competition, particularly from Asian countries with lower labor costs, made their manufactured products more competitive. This shift led to a decline in domestic manufacturing jobs, sparking debates about tariffs and job repatriation. The once-thriving industries of tobacco, textiles, and furniture faced significant challenges, leading to a transformation in the state’s manufacturing landscape.

As North Carolina faced these challenges, the state also had to contend with advances in technology and automation. These advancements rendered some traditional manufacturing processes obsolete and heightened the pressure on local industries to innovate or shut down. The exodus of jobs to countries with cheaper labor costs created economic ripples throughout communities that once thrived on manufacturing. Residents faced uncertainty and economic displacement, forcing a rethinking of the state’s economic strategy. The decline of traditional manufacturing markets resulted in a significant realignment of North Carolina’s industrial priorities, ushering in a new era of innovation and technological investment.

Recent Developments and Current Status

Post-Pandemic Recovery

In the post-pandemic era, North Carolina’s manufacturing sector has shown signs of recovery. The value of manufacturing production has returned to and slightly surpassed pre-pandemic levels, with a 1% increase since 2019. However, this growth is modest compared to the national increase of 7% over the same period. Despite this, North Carolina’s total economic activity surged by 16% from 2019 to 2024, outpacing the national growth of 12%.

This disparity between North Carolina’s modest manufacturing growth and its substantial overall economic activity points to an underlying economic transformation. Other burgeoning sectors, possibly outside traditional manufacturing, seem to be driving this economic upsurge. The state’s robust recovery and growth can be attributed to its adaptive economy and strategic investments in emerging industries and technology. The resilience demonstrated by North Carolina during and after the pandemic has set a strong foundation for future development and economic expansion.

Employment Trends

On the employment front, North Carolina experienced a 3% decline in manufacturing jobs between 2019 and 2024, while the nation saw a 1% increase. Interestingly, overall job growth in the state was robust, with a 9% increase, nearly double the national gain of 5%. The average hourly wage rate for manufacturing jobs in North Carolina rose by 28% during this period, surpassing the 22% consumer price inflation and the national manufacturing wage increase of 23%.

These employment trends paint a contrasting picture. While manufacturing jobs are on the decline, the increase in wages might indicate a higher demand for skilled labor. This wage growth suggests that the remaining manufacturing roles require more advanced skills, possibly reflecting a shift towards more technologically advanced manufacturing processes. Despite the decline in job numbers, the sector remains crucial, contributing significantly to the state’s economy. It also underscores a pivotal transformation where the value of the manufacturing workforce is elevated due to necessary upskilling and specialization.

Analysis and Key Points

Shifts in Manufacturing Sectors

A deeper analysis reveals a significant shift in North Carolina’s manufacturing landscape. Traditional sectors like tobacco, textiles, furniture, and paper industries have declined, while production in pharmaceuticals, technology, metal manufacturing, mining, and transportation sectors has risen. This transition from traditional to modern manufacturing sectors is the primary reason for the slower pace of manufacturing growth in North Carolina compared to the nation. Job losses in traditional sectors accounted for 90% of the state’s overall drop in manufacturing jobs from 2019 to 2024.

This industrial shift highlights the state’s evolution from its historical economic foundations to a modernized, diversified manufacturing economy. New sectors are emerging as powerhouses, contributing to growth and resilience. Sectors such as pharmaceuticals and technology are not only more resistant to international competition but also align with the global trend toward innovation and high-tech manufacturing. This transition is essential for the state’s long-term economic sustainability and competitive edge in both national and global markets.

Wage Increases and Labor Market Trends

Despite the drop in job numbers, there has been a noticeable increase in pay rates in manufacturing. This anomaly can be attributed to the multitude of job vacancies in the sector. Many studies suggest that younger generations are disinterested in manufacturing jobs, perceiving them as labor-intensive and demanding long hours. Despite these perceptions possibly being outdated, the rapid growth of North Carolina presents plenty of more attractive job opportunities in other sectors for young workers. Consequently, manufacturers have been compelled to offer significantly higher wages to attract labor.

The increased wages highlight a critical issue for North Carolina’s manufacturing sector: attracting and retaining a skilled workforce amid a competitive job market. As traditional perceptions of manufacturing jobs linger, there is a pressing need for the industry to reinvent its image to appeal to newer generations. Addressing these labor market challenges involves creating awareness about the advancements in manufacturing, which include smart factories, automation, and technology-driven environments. Highlighting these aspects could shift the narrative and make manufacturing an appealing and viable career choice for younger generations.

Future Outlook

Emerging Industries and Technological Advancements

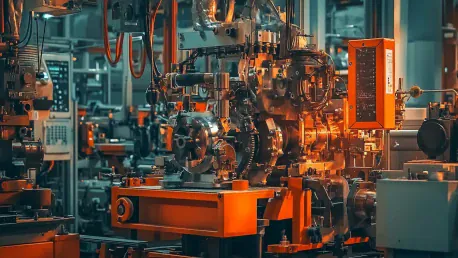

Looking ahead, manufacturing is expected to remain pivotal to North Carolina’s economy, albeit in an evolved form. The future will likely see continued growth in sectors such as technology and pharmaceuticals. Emerging industries in aeronautics, vehicle production, computer chips, and battery manufacturing also show promise for expansion. These sectors are poised to drive the next wave of growth in North Carolina’s manufacturing landscape.

The focus on these burgeoning sectors reflects a strategic pivot towards high-growth and forward-looking industries. Investments in research and development, coupled with the state’s supportive infrastructure, are fostering an environment conducive to innovation. North Carolina is well-positioned to capitalize on the technological advancements defining modern manufacturing. By leveraging its academic institutions, research facilities, and skilled workforce, the state can continue to attract significant investments and partnerships, further solidifying its position as a leader in advanced manufacturing.

The Role of Artificial Intelligence

Manufacturing has played a pivotal role in North Carolina’s economic development for a long time. The transition began in the 19th century when manufacturing began to surpass agriculture as the main economic driver of the state. Over the years, the manufacturing industry has seen significant shifts and transformations, adapting to various economic climates and technological advancements. Today, North Carolina finds itself at a crucial juncture. It honors a rich historical legacy of manufacturing excellence while simultaneously embracing a future driven by technological integration and modernization. The state’s manufacturing sector is now looking toward incorporating advanced technologies like automation, Artificial Intelligence, and sustainable practices to maintain its competitive edge. This modernization aims to build on North Carolina’s strong manufacturing foundation, driving economic growth well into the future. The challenge lies in striking the right balance between preserving the proud heritage of manufacturing and moving confidently into a technologically advanced era. They look forward to new opportunities while honoring past achievements.