The clothing we wear every day has a hidden story, one that often begins not in a field of cotton, but deep underground in deposits of crude oil. For decades, the global textile industry has been overwhelmingly dependent on fossil fuels to create synthetic fibers like polyester and nylon, contributing significantly to global pollution and greenhouse gas emissions. This reliance has placed the fashion world at a critical juncture, faced with a choice between continuing its environmentally burdensome practices or embracing a revolutionary shift in material science. Now, an alternative is taking root, one that swaps the oil derrick for the farm and the laboratory. Bio-based polymers, innovative materials derived from renewable biological sources, are emerging from the fringes to challenge the status quo, offering a compelling, though not yet perfect, pathway toward a more sustainable and circular future for the fabrics that clothe our world.

The Science of Sustainable Fibers

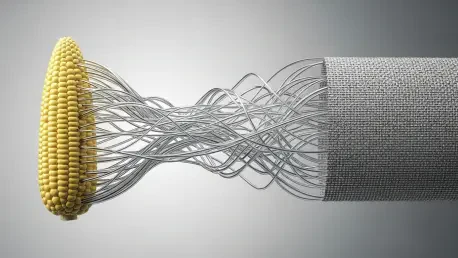

At its core, a bio-based polymer is a material whose fundamental building blocks are sourced from the natural world rather than a petrochemical plant, utilizing a diverse array of renewable feedstocks such as corn starch, sugarcane, plant oils, and even fungi. The primary advantage of these materials lies in their ability to replace the fossil-derived carbon that forms the very foundation of conventional synthetics. This fundamental switch is critically important for reducing the industry’s deep-seated dependence on finite, non-renewable resources. More importantly, it holds the potential to significantly lower the overall greenhouse gas emissions associated with a material’s entire lifecycle, from creation to disposal. By harnessing the carbon cycles of the natural world, these textiles represent a move away from an extractive model and toward a regenerative one, fundamentally altering the environmental equation of fashion production and offering a tangible way to lessen the industry’s considerable carbon footprint.

Beyond their sustainable origins, the end-of-life potential of many bio-based polymers offers another crucial environmental benefit that addresses one of the textile industry’s most persistent problems. A significant advantage of certain bio-polymers is their capacity for managed degradation or enhanced recyclability, attributes that enable the creation of more circular material pathways. This directly combats the long-term accumulation of textile waste in landfills and mitigates the pervasive issue of microplastic pollution that contaminates natural ecosystems. The portfolio of these materials is remarkably diverse, with options like polylactic acid (PLA), polyhydroxyalkanoates (PHA), and regenerated cellulose derivatives each possessing a unique profile of properties, including biodegradability, moisture management, durability, and thermal behavior. This rich variety makes the category both full of possibilities and technically complex, allowing for tailored solutions that can meet a wide range of performance and aesthetic demands without the long-term environmental cost of traditional plastics.

Meet the Next Generation of Materials

Leading the charge in this material revolution is Polylactic Acid (PLA), one of the most commercially mature and widely adopted bio-based polymers. Produced through the microbial fermentation of sugars derived from crops like corn and sugarcane, PLA can be expertly spun into fibers that are highly competitive with conventional polyester in terms of performance. Its key attributes include excellent breathability, a lower energy requirement during processing, and, most notably, the ability to biodegrade under industrial composting conditions. The industrial momentum behind PLA is significant, with forecasts predicting that global production capacity will surge from approximately 460,000 metric tons to over 2.3 million metric tons in the next few years. Its applications are already widespread, appearing in performance apparel, activewear, and nonwovens where moisture-wicking properties and a reduced carbon footprint are highly valued. Commercial examples, such as Acme Mills’ Natura line, demonstrate its viability in the mainstream market.

While PLA sets a strong precedent, other innovative materials are expanding the possibilities of bio-based textiles even further. Polyhydroxyalkanoates (PHA), a class of polymers synthesized by bacteria during fermentation, offer a crucial advantage: many variants are fully biodegradable in a wide range of natural environments, including sensitive marine ecosystems. This characteristic makes PHA a particularly powerful tool in the fight against the microplastic pollution that originates from textile shedding. In a different vein, bio-based polyamides, often derived from renewable feedstocks like castor oil, are positioned as high-performance, sustainable alternatives to conventional nylon. These materials are being adopted in technical textiles and demanding applications like sportswear and outerwear without compromising on durability or function. Alongside these newcomers, regenerated cellulosic fibers like Lyocell and modal, derived from wood pulp, continue to succeed by merging strong sustainability credentials with consumer-appreciated qualities. Produced using closed-loop processes that recycle solvents, they offer exceptional softness and an elegant drape, proving that eco-consciousness and luxury can coexist.

From Lab to Label The Market Reality

The transition of bio-based polymers from conceptual research to commercial reality is no longer a future speculation but a present-day fact, evidenced by a growing number of collaborations between material innovators and major fashion brands. Industry leader NatureWorks LLC’s Ingeo PLA fiber is now being utilized by over 80 global brands, including outdoor apparel giant Patagonia, which has integrated it into its product lines. In another high-profile partnership, chemical company BASF SE has worked with retail powerhouse Inditex to develop fully bio-sourced garments. The wave of innovation is also reaching the highest tiers of the industry, with cutting-edge biotechnology firms like MycoWorks, which uses mycelium to create leather-like materials, and Bolt Threads, which is developing recombinant spider silk, introducing these novel textiles into the world of luxury fashion. Further demonstrating market readiness, Taekwang Industry’s ACECOOL-BIO, a plant-based nylon, boasts a 50% reduction in carbon emissions and enhanced breathability, making it a compelling choice for the competitive activewear sector.

This powerful commercial momentum is strongly supported by a significant cultural shift in consumer behavior, particularly among Millennial and Gen Z demographics who are increasingly factoring environmental impact into their purchasing decisions. Research indicates that over 60% of consumers in developed markets are willing to pay a premium for sustainable textiles, validating this trend and empowering brands to leverage material innovation as a key market differentiator. Despite this promising outlook, several significant challenges currently constrain widespread adoption. Bio-based materials often carry a cost premium of 15–30% compared to their fossil-derived counterparts. Critical infrastructure gaps also exist, as the industrial composting facilities and specialized recycling systems required for proper end-of-life management are not yet globally available. Finally, performance trade-offs remain a concern in certain technical applications, where some bio-based fibers have yet to match the established durability and versatility of conventional synthetics, highlighting areas where further research and development are needed.

Weaving a Responsible Tomorrow

In the final analysis, the rise of bio-based polymers represented a fundamental and indispensable lever in the fashion industry’s broader transition toward sustainability. While these materials were not a singular solution to all of the sector’s complex environmental problems, they successfully reshaped the landscape of textile production by reducing fossil fuel dependency and mitigating ecological impacts. Their trajectory involved a concerted effort to scale production to achieve cost parity, continuous research to enhance performance characteristics, and a rising tide of consumer demand that drove mainstream adoption. The successful, large-scale integration of these materials ultimately depended on coordinated investment across the entire supply chain, robust regulatory support for green technologies, and the establishment of clear, industry-wide standards for certification, traceability, and end-of-life management. This comprehensive approach was essential for building consumer confidence and forging a future where fashion was simultaneously expressive, ecologically responsible, and commercially successful.