Imagine a future where the strongest metals and ceramics are sculpted with the finesse of an artist’s brush, all through the power of 3D printing technology, and now, a pioneering team led by Daryl Yee at EPFL’s Laboratory for the Chemistry of Materials and Manufacturing has turned this vision into reality with a cutting-edge approach to additive manufacturing. This breakthrough method is shattering the limitations of traditional 3D printing, enabling the creation of ultra-strong materials with unparalleled precision. Industries ranging from aerospace to biomedical engineering stand to benefit from components that balance intricate design with exceptional durability. By tackling long-standing challenges in material fabrication, this innovation marks a significant step forward, promising to reshape how high-performance parts are produced and opening doors to applications previously thought impossible.

Breaking New Ground in Additive Manufacturing

Overcoming Old Barriers

Traditional 3D printing techniques, such as vat photopolymerization, have long been celebrated for their ability to craft highly detailed polymer structures by curing light-sensitive resins with precision. However, when applied to metals and ceramics, these methods often stumble, producing materials plagued by porosity—tiny holes that weaken the structure—and extreme shrinkage during processing, sometimes as much as 90%. Such flaws severely limit the reliability and accuracy of the final product, making it unsuitable for demanding applications like aircraft components or medical implants. The inability to maintain structural integrity has kept these materials out of critical industries where strength and precision are non-negotiable, creating a persistent gap in additive manufacturing capabilities.

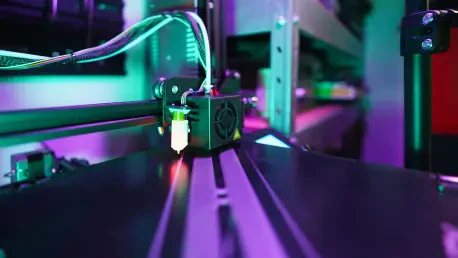

The EPFL team’s solution introduces a transformative approach by utilizing a hydrogel-based scaffold as the foundation for crafting complex designs. This water-rich polymer matrix, created through vat photopolymerization, acts as a precise, inert template that sidesteps the issues of direct metal integration during printing. Unlike conventional methods where metal precursors are mixed into resins from the start, this technique focuses on shaping first, ensuring intricate geometries are achieved with exceptional spatial control. The hydrogel structure serves as a blank canvas, allowing for detailed architectures that retain their form through subsequent stages, addressing the critical problem of dimensional accuracy in a way that traditional processes never could.

A Step-by-Step Revolution

Once the hydrogel scaffold is printed with meticulous detail, the next phase involves infusing it with metal ions such as iron, silver, or copper through a repeated soaking process. This method entails immersing the scaffold in metal salt solutions, followed by chemical treatments that convert the ions into nanoscale particles embedded within the polymer network. By cycling through this infusion-precipitation process multiple times—often five to ten rounds—the team achieves a high concentration of metal content while preserving the original design’s complexity. This step-by-step buildup ensures that the material is densely packed without compromising the intricate shapes, marking a significant departure from older techniques where early mixing led to uneven distribution and structural flaws.

The transformation culminates in a controlled heating process known as calcination, which removes the hydrogel scaffold by turning it into vapor, leaving behind a solid metal or ceramic structure. Remarkably, this method reduces shrinkage to a mere 20%, a dramatic improvement over the 60-90% seen in conventional approaches. The resulting lattice retains the detailed architecture of the initial design with minimal defects, ensuring both dimensional fidelity and robustness. This final step not only solidifies the material but also highlights the precision of the process, as the low shrinkage rate means that even the most complex geometries can be reliably reproduced, offering a level of consistency that sets a new standard for additive manufacturing of high-strength components.

Unmatched Strength and Versatility

Superior Performance

Testing of the materials produced through this innovative method has revealed extraordinary mechanical strength, far surpassing what traditional 3D printing techniques can achieve. Complex lattice designs, such as gyroids, which feature high surface-to-volume ratios, have demonstrated the ability to withstand pressures up to 20 times greater than those made with existing polymer-to-metal conversion processes. This exceptional durability stems from the dense, defect-free structures created by the hydrogel-based approach, which minimizes weaknesses like porosity. The implications are profound for industries where lightweight yet robust components are essential, as these materials can endure extreme conditions without sacrificing intricate design elements critical for functionality.

Beyond raw strength, the performance of these materials also shines in their ability to maintain structural integrity under stress, a key factor for real-world applications. The reduced shrinkage during processing ensures that the final product closely matches the intended design, avoiding the distortions that often plague conventionally printed metals and ceramics. This precision, combined with superior load-bearing capacity, positions the technology as a game-changer for creating parts like turbine blades or orthopedic implants, where even minor deviations can lead to failure. The proven resilience of these structures underscores the potential to redefine standards in material engineering, pushing the boundaries of what additive manufacturing can accomplish.

Customizable Solutions

One of the most striking advantages of this new technique lies in its remarkable flexibility, allowing a single hydrogel scaffold to be transformed into a variety of metals or ceramics based on the choice of metal salts used during infusion. This decoupling of shape creation from material composition means that manufacturers can decide on the final material at a later stage, facilitating rapid prototyping and tailored solutions for specific needs. Whether the goal is to produce a lightweight silver structure for thermal conductivity or a tough ceramic for high-temperature resistance, the process adapts seamlessly, offering unprecedented versatility in material selection that traditional methods cannot match.

This adaptability also paves the way for innovation in design and application, as engineers can experiment with different material outcomes without needing to redesign or reprint the initial scaffold. Such flexibility is particularly valuable in fields like biomedical engineering, where customized implants might require varying compositions for biocompatibility or strength, or in energy technologies, where catalytic properties depend on specific metals. By enabling late-stage customization, the method reduces production timelines and costs associated with iterative testing, fostering a more agile approach to developing functional materials. This capacity to pivot material choices post-printing heralds a shift toward more dynamic and responsive manufacturing processes.

Looking Ahead: Challenges and Potential

Scaling Up

Despite the groundbreaking nature of this hydrogel-based 3D printing technique, a significant hurdle remains in its scalability for industrial use, primarily due to the time-intensive nature of the multiple infusion cycles required to achieve high metal loadings. Each cycle of soaking and chemical treatment, while crucial for ensuring material density and design fidelity, adds to the overall production timeline, making large-scale manufacturing a challenge at present. This limitation poses a barrier to widespread adoption in industries that demand high throughput, as the current process prioritizes precision and strength over speed, necessitating a balance that has yet to be fully realized for mass production environments.

Efforts to overcome this obstacle are already underway, with the EPFL team exploring automation strategies to streamline the infusion and treatment phases. Innovations such as robotic handling and optimized cycle durations aim to reduce the manual labor and time associated with each step, potentially bringing the technology closer to commercial viability. If successful, these advancements could transform the method into a practical solution for producing ultra-strong components on a larger scale, meeting the needs of industries like aerospace and energy conversion. The focus on enhancing efficiency without compromising quality reflects a commitment to bridging the gap between experimental success and real-world application.

Future Horizons

Looking to the future, the potential of this technology extends beyond immediate scalability concerns, hinting at broader implications for additive manufacturing as a whole. Continued research into increasing the density of final materials and refining the chemical processes involved could further elevate the strength and range of applicable materials, expanding the scope of what can be achieved. The conceptual shift of separating form from material selection also suggests possibilities for recycling or repurposing scaffolds, aligning with growing demands for sustainable manufacturing practices that minimize waste and resource consumption in high-tech industries.

Moreover, the cross-disciplinary nature of this innovation—drawing on insights from materials science and biomedical applications of hydrogels—points to a trend of integrating diverse fields to solve complex engineering challenges. As automation and process optimization progress, the technique could inspire new workflows in 3D printing, where flexibility and precision become standard rather than exceptional. Reflecting on the strides made, this method has already laid a foundation for rethinking how ultra-strong materials are crafted, and its evolution promises to drive further breakthroughs in creating components that meet the rigorous demands of tomorrow’s technologies.