The global shift towards sustainable consumer goods is placing unprecedented pressure on manufacturers to innovate, particularly in the single-use personal hygiene market where performance and environmental impact are under constant scrutiny. Responding decisively to this challenge, the world’s largest pulp producer, Suzano, has launched a landmark expansion at its Limeira facility in Brazil. A significant R$490 million investment has fueled the creation of a new fluff pulp production line, catapulting the company’s annual capacity from 100,000 to an impressive 440,000 metric tons—an increase of over 400%. This project involved a sophisticated upgrade of an existing line, transforming it into a flexible machine capable of producing not only standard market pulp for products like toilet paper and packaging but also the company’s proprietary and highly specialized Eucafluff®. This strategic move signals a major commitment to bio-based materials and prepares the company to meet the escalating needs of a market that increasingly values both premium quality and environmental responsibility.

Innovating Personal Hygiene with Eucafluff

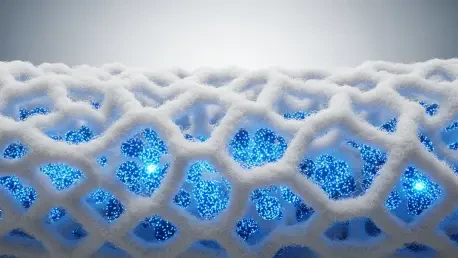

At the core of this major industrial expansion is Eucafluff®, a revolutionary material that stands as the world’s first fluff pulp derived entirely from eucalyptus. It has been specifically engineered to meet the high-performance demands of the absorbent personal hygiene products sector, a category that includes baby diapers, adult incontinence products, and sanitary pads. What distinguishes this material are its unique physical properties, which include enhanced softness and remarkable flexibility—critical attributes for consumer comfort and product design. These characteristics empower manufacturers to create goods that are significantly thinner, more comfortable, and more discreet than those made with conventional materials. Beyond the improved feel and fit, products incorporating Eucafluff® also demonstrate superior functional performance. Extensive testing has confirmed its advanced capabilities in liquid retention and rewet prevention, ensuring a drier and more secure experience for the end-user. This powerful combination of comfort and high-level performance directly addresses key consumer preferences.

A Strategic Move Toward a Greener Future

This major capacity increase represented more than a simple production upgrade; it was a deliberate and strategic step toward a more sustainable manufacturing paradigm for the entire industry. A key environmental advantage of Eucafluff® stemmed from its high compression capability, a property that allowed for a significant reduction in the final product’s packaging size and directly translated to lower plastic consumption. Furthermore, smaller, more compact packages reduced transportation costs and the associated carbon footprint, creating a positive ripple effect throughout the supply chain. The environmental credentials of this eucalyptus-based fluff were further validated by a comprehensive Life Cycle Analysis conducted in 2024, which confirmed its more favorable environmental profile when compared to traditional pine-based fluff pulp. This investment was a cornerstone of Suzano’s overarching strategy to champion renewable solutions. By substantially increasing the availability of this innovative product, the company effectively positioned itself to meet rising global demand and solidified its leadership in a market pivoting towards sustainability.