A revolutionary carbon-free annealing system developed by researchers at the Korea Institute of Energy Research (KIER) is set to redefine the manufacturing of galvanized steel, a cornerstone material for the global automotive and home appliance industries. This pioneering electric furnace technology completely sidesteps the use of fossil fuels in a critical heat treatment stage, presenting a powerful and practical solution to one of the most stubborn challenges in industrial decarbonization. By offering a clean, efficient, and commercially viable alternative to traditional methods, this innovation represents a monumental leap forward in the quest for green steel, aligning with ambitious climate targets and signaling a new era for sustainable heavy industry. The system’s successful demonstration confirms that environmental responsibility and high-quality industrial production are no longer mutually exclusive goals, but achievable realities through targeted technological advancement.

The Imperative for Decarbonized Manufacturing

Navigating Global Climate Pressures

The global industrial sector is currently navigating a period of unprecedented transformation, driven by stringent environmental mandates and evolving economic landscapes. Nations worldwide are committing to aggressive greenhouse gas reduction targets, such as Korea’s goal to slash industrial emissions by up to 31% from 2018 levels by 2035, placing immense pressure on historically carbon-intensive industries like steelmaking. This domestic pressure is compounded by international policies, most notably the European Union’s Carbon Border Adjustment Mechanism (CBAM), which effectively places a carbon tax on imported goods. For export-reliant economies, this mechanism transforms decarbonization from an environmental ideal into a critical economic necessity. Companies that fail to adapt risk facing significant financial penalties, rendering their products uncompetitive in key global markets. This new reality forces industries to urgently seek out and adopt innovative, low-carbon production methods not merely for compliance, but for their very survival and continued relevance.

This shift toward green manufacturing is fostering a powerful consensus that the transition to cleaner technologies is not only environmentally imperative but also technologically feasible and economically advantageous. The development of electrified industrial processes demonstrates that deep decarbonization can be achieved without compromising the quality or productivity that define modern manufacturing. Innovations like the carbon-free annealing furnace serve as proof that replacing legacy, fossil-fuel-based systems with clean, electricity-powered alternatives is a viable strategy. For nations heavily invested in manufacturing and international trade, embracing these technologies is a proactive measure to safeguard economic stability. By preemptively adopting processes that align with global standards like the CBAM, these countries can ensure their products remain attractive and tariff-free, securing their competitive edge in a rapidly evolving, climate-conscious global marketplace and positioning themselves as leaders in the sustainable economy of the future.

The Carbon Footprint of Conventional Steel

The conventional method for producing galvanized steel strips involves a continuous galvanizing line (CGL), a sophisticated process where steel plates are coated in molten zinc to prevent corrosion. A vital step within this line is annealing, a heat treatment where the steel is subjected to controlled heating and cooling to enhance its ductility and formability, making it suitable for complex shaping in applications like car bodies and home appliances. Traditionally, the immense thermal energy required for the annealing furnace is generated by the combustion of fossil fuels, predominantly natural gas. This process is inherently carbon-intensive, releasing substantial quantities of greenhouse gases directly into the atmosphere, including carbon dioxide (CO2) and nitrogen oxides (NOx). The sheer scale of this issue is significant; in a major industrial nation like Korea, the steel industry, including zinc manufacturing, accounts for approximately 15% of the country’s total carbon emissions, making it a primary and urgent target for comprehensive decarbonization efforts.

Beyond its significant CO2 emissions, the reliance on fossil fuel combustion presents a host of other environmental and operational challenges that underscore the need for a technological paradigm shift. The combustion process itself is not perfectly efficient, leading to energy losses and the production of secondary pollutants that require complex and costly exhaust and scrubbing systems to manage. Furthermore, the infrastructure associated with natural gas—including pipelines, storage facilities, burners, and air supply systems—is extensive and capital-intensive, contributing to a large physical footprint and ongoing maintenance costs. The inherent volatility of fossil fuel prices also introduces a level of economic uncertainty for manufacturers. A transition to an electrified process addresses these issues holistically, moving beyond a simple reduction in emissions to create a fundamentally cleaner, more efficient, and economically stable manufacturing ecosystem. It represents a complete reimagining of the energy source, paving the way for a more sustainable and resilient industrial future.

A Groundbreaking Technological Shift

Engineering an Electric-Powered Solution

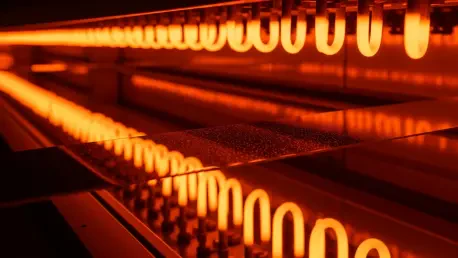

The ingenious carbon-free annealing system developed by the KIER research team, led by Dr. Hookyung Lee, represents a major breakthrough in industrial heating technology. Instead of designing a new furnace from scratch, the team adopted a clever retrofitting approach that leverages existing infrastructure, making the transition more accessible and cost-effective. They retained the fundamental refractory structure and the steel-strip conveying mechanism of a conventional furnace but strategically replaced the fossil fuel burners with advanced electric heating elements. These elements were installed in both the upper and lower sections of the furnace, creating a comprehensive heating environment. The core of this proprietary innovation lies in the precise engineering of the spatial relationship between these heating elements and the moving steel strip. By meticulously optimizing this distance, the system is able to deliver exceptionally rapid and uniform heating through the power of high-temperature radiant heat, a method that is both powerful and highly controllable.

This focus on direct radiant heat is what sets the technology apart, maximizing its energy efficiency and performance. Unlike combustion-based systems, which heat the air within the furnace, the electric elements transfer thermal energy directly to the surface of the steel strip. This method drastically minimizes heat loss to the furnace walls and surrounding components, ensuring that the vast majority of the electrical energy consumed is converted into useful heat for the annealing process. This direct and targeted approach not only accelerates the heating cycle but also provides superior temperature control, which is critical for achieving the desired metallurgical properties in the final product. The successful implementation of this concept—a direct and relatively simple replacement of the heat source within an established industrial application—has been presented as a world-first demonstration, highlighting its pioneering status and its potential to serve as a blueprint for electrifying other high-temperature industrial processes globally.

Validated Performance and Far-Reaching Benefits

To validate its real-world viability, the electrified annealing technology underwent rigorous testing under conditions meticulously designed to simulate a commercial production environment. During these trials, the system was used to anneal steel strips with a thickness of 0.49 millimeters at a target temperature of 750°C. The results were nothing short of remarkable, particularly concerning its environmental impact. The electrified process led to a drastic reduction in harmful emissions, slashing the concentrations of both carbon dioxide and nitrogen oxides in the exhaust gases by more than 98% when compared to conventional combustion-based methods. This near-total elimination of direct process emissions stands as the technology’s most significant achievement and a cornerstone of its value proposition. It offers a tangible and immediate solution for steelmakers aiming to meet stringent environmental regulations and drastically reduce their carbon footprint, proving that industrial-scale greening is not a distant goal but an achievable reality.

Crucially, the transition to electric heating was accomplished without any negative impact on the final product, a critical factor for adoption in demanding sectors like automotive manufacturing. Extensive analysis confirmed that the annealed steel strips exhibited color, microstructure, and mechanical properties that were equivalent to those produced using traditional gas-fired furnaces. This parity is essential, as it assures manufacturers that they can embrace this clean technology without compromising the high-quality standards their customers expect. The findings collectively demonstrate that, with thoughtful design and precise operation, deep decarbonization is possible while maintaining existing levels of productivity and product integrity. This synergy of environmental benefit and uncompromised quality is what makes the technology so compelling, offering a clear and attractive pathway for the industry to evolve sustainably.

Charting a Course for a Greener Industrial Future

The development of this electric furnace marked a pivotal moment, and its strategic implications were immediately clear. Beyond its profound environmental benefits, the system offered significant economic advantages by eliminating the need for the complex infrastructure tied to fossil fuels, such as burners and exhaust systems, thereby reducing capital investment costs and the required installation footprint by an estimated 40%. When integrated with renewable energy sources, it enabled a genuinely carbon-neutral heat treatment process, providing a powerful strategic advantage in an era of tightening global environmental regulations like the CBAM. Looking ahead, the research team laid out an ambitious roadmap for the technology’s future, centered on the creation of an AI-based design and operation system. This intelligent platform was envisioned to automatically recommend optimal configurations based on real-time variables, further enhancing efficiency and adaptability. The ultimate goal was to scale up the technology through commercial-scale demonstrations and package it as a comprehensive, export-ready solution, solidifying its position as a leading innovation that could redefine industrial decarbonization on a global scale.