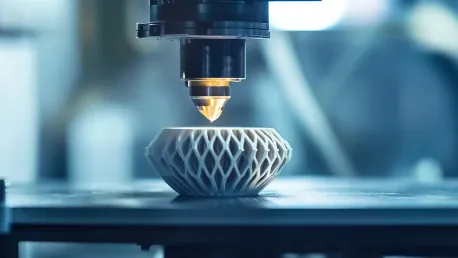

Atlas Copco's recent shift to polymer-based additive manufacturing (AM) has revolutionized its production processes, showcasing dramatic improvements in cost efficiency, lead times, and environmental sustainability. Leveraging advanced EOS technology, this transformation aligns with broader

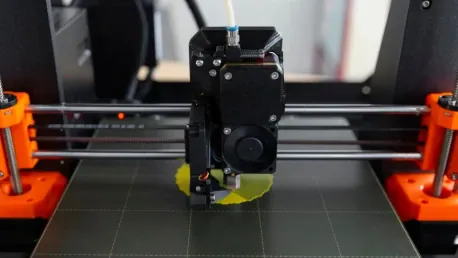

3D printing technology, sometimes referred to as additive manufacturing, is making waves in the automotive industry by dramatically transforming how vehicles are designed, produced, and customized. Automakers are leveraging this cutting-edge technology to enhance design processes, streamline

Interspectral, a leading SaaS provider specializing in AI-driven quality assurance and process monitoring solutions, has recently completed a new round of investment led by Navigare Ventures, a prominent Swedish investor in industrial innovation and deep tech. This strategic funding is set to

The integration of Hot Isostatic Pressing (HIP) technology into the realm of Additive Manufacturing (AM) marks a significant advancement in the production of high-performance parts. By leveraging HIP, companies are able to overcome traditional limitations, optimizing the mechanical properties and

The high-tech drone industry is in the midst of a transformative period, and much of this change is driven by advanced manufacturing technologies. Notably, Unusual Machines, Inc., a company known for its cutting-edge First-Person View (FPV) drones, has adopted HP’s Multi-Jet Fusion (MJF) 3D

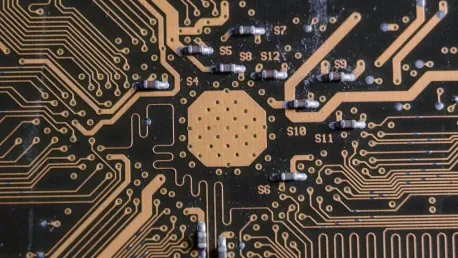

In a groundbreaking development for the electronics industry, Japanese startup Elephantech has introduced an innovative manufacturing technology that aims to significantly reduce the environmental impact of producing Printed Circuit Boards (PCBs). Employing a pioneering method of metal inkjet