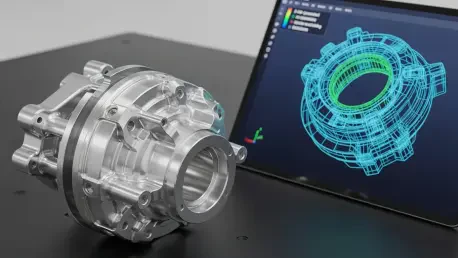

The world of additive manufacturing, with its breakneck speed and single-button simplicity, often stands in stark contrast to the traditional, labor-intensive processes of subtractive manufacturing. For decades, turning a digital 3D model into a precision-milled metal component has remained a craft

The impending transformation of computer-aided design, driven by artificial intelligence, is not about creating autonomous machines that render human engineers obsolete but about forging a powerful partnership that amplifies human creativity. By 2026, AI is poised to become a deeply integrated

The hum of a modern industrial facility is a symphony of precision, where automated systems and intelligent robots execute tasks with seamless coordination, yet this entire operation hinges on an invisible and increasingly fragile foundation. As industries aggressively integrate automation and

The intricate web of global manufacturing, once a testament to efficiency, has been severely tested by persistent supply chain bottlenecks that began in 2019, forcing industries to innovate or face crippling delays. In this challenging environment, aerospace giant Airbus has executed a remarkable

The relentless pressure for perfect production runs has pushed traditional manufacturing models to their breaking point, where even the smallest deviation can trigger a cascade of costly downtime and quality failures. In response to this challenge, a new operational paradigm is emerging, one that

A startling new reality was on full display at the recent International Robot Exhibition in Tokyo, where the most advanced and captivating humanoid machines were not the product of Japanese innovation but were instead developed by Chinese firms. This tectonic shift in the global robotics landscape