In a world where industrial innovation races ahead at breakneck speed, additive manufacturing stands as a cornerstone for transforming how products are designed and produced across countless sectors. At Formnext, a flagship event for the 3D printing industry held this year, HP emerged as a dominant

In a world where manufacturing demands are shifting toward speed, customization, and sustainability, a Silicon Valley innovator has taken a significant step forward with a major financial boost. Carbon, a trailblazer in additive manufacturing, has recently raised $60 million in funding, marking a

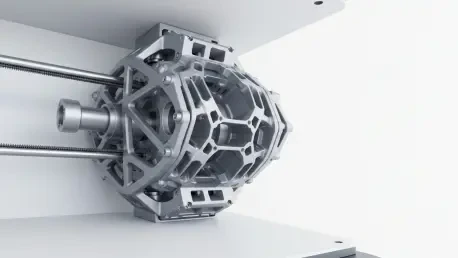

Metal Additive Manufacturing (AM) stands at the forefront of a manufacturing revolution, with the global market projected to grow at a staggering compound annual growth rate of over 20% from 2025 to 2030, driven by the urgent need for customized, lightweight components across critical industries

In an era where manufacturing faces relentless pressure to innovate, how can a single facility redefine an entire industry? CNPC Powder, a Vancouver-based leader in additive manufacturing (AM), has stepped boldly into this challenge with the launch of a groundbreaking hub in Shanghai, China. Known

As we dive into the cutting-edge world of additive manufacturing, I’m thrilled to chat with Kwame Zaire, a renowned expert in manufacturing with a deep focus on electronics, equipment, and production management. Kwame has established himself as a thought leader in predictive maintenance, quality,

Imagine a world where the aerospace and automotive industries rely on materials so lightweight yet incredibly strong that they redefine the boundaries of design and efficiency, pushing the limits of what is possible. This vision is inching closer to reality with the emergence of advanced