The convergence of artificial intelligence and physical manufacturing is rapidly reshaping the creative landscape, promising a future where the journey from a digital concept to a tangible object is more intuitive and accessible than ever before. In a landmark move at CES 2026, consumer-tech brand

The industrial polymer additive manufacturing market is currently navigating a period of profound transformation, characterized by a fundamental tension between established high-performance systems and the disruptive force of increasingly capable low-cost desktop printers. For incumbent original

In the highly competitive landscape of modern industrial production, the margin for error has effectively vanished, making the consistent delivery of high-precision components not just an advantage but a fundamental requirement for success. FZE Manufacturing Solutions, a contract manufacturer based

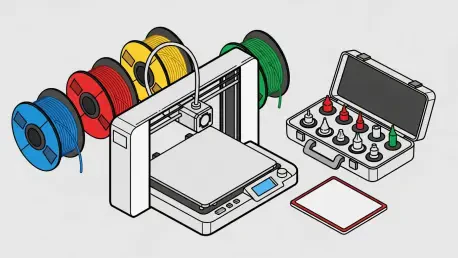

Once confined to the high-tech laboratories of industrial giants and research institutions, the revolutionary power of 3D printing has now firmly entered the mainstream, transforming how we conceptualize, design, and create. This shift from an exclusive industrial process to a widely accessible

A seismic shift is reconfiguring the foundations of global pharmaceutical production, with hundreds of billions of dollars in capital now flowing back toward American shores to rebuild a domestic manufacturing base that was offshored over decades. This monumental pivot is not a matter of chance but

The modern manufacturing floor, a landscape brimming with autonomous robotics, AI-driven analytics, and intricate cyber-physical systems, bears little resemblance to the assembly lines of the past, yet a persistent and damaging perception gap threatens to stall its progress. This disconnect between