For years, the immense potential of lightweight, high-strength reactive metals in additive manufacturing has been shadowed by the inherent difficulty and danger of processing them, relegating many advanced alloys to the realm of research rather than production. The very properties that make

While the digital alarms in manufacturing boardrooms have been ringing loudest for the ever-present threat of ransomware, a more insidious and politically charged danger has quietly moved from the periphery to the factory floor. For years, the sector has rightly focused its defenses on financially

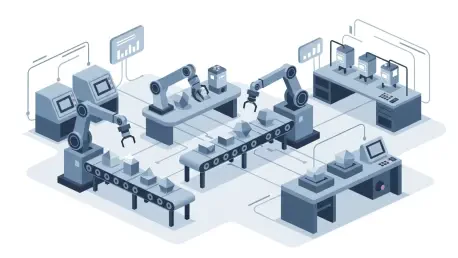

The operational heart of the modern factory floor is no longer just the machinery itself, but the sophisticated digital interfaces that control and interpret every process in real time. This critical nexus of human and machine interaction is driving an unprecedented expansion in the industrial

The global industrial control and factory automation market is on an unprecedented trajectory, with projections indicating it will more than double in value, rocketing from USD 226.85 billion in 2025 to an estimated USD 461.36 billion by 2031. This remarkable expansion, representing a compound

The global chemical industry operates on a razor's edge where even the slightest deviation in temperature or pressure can lead to compromised products, significant financial loss, or catastrophic safety failures. For manufacturers navigating this high-stakes environment, the selection of a thermal

As robotics technology continues its relentless march forward, creating machines with unprecedented intelligence and complexity, their ultimate effectiveness in the real world is increasingly dictated not by their software but by the precision of their physical hardware. The most advanced control