A surge of economic optimism swept through U.S. markets, driving major indexes toward record highs on the back of a manufacturing report that significantly outpaced expectations. This broad-based rally, however, masked a turbulent undercurrent of sector-specific volatility where news of regulatory

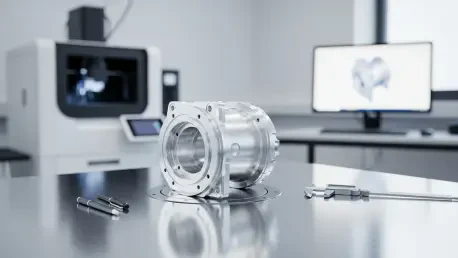

For years, the immense potential of lightweight, high-strength reactive metals in additive manufacturing has been shadowed by the inherent difficulty and danger of processing them, relegating many advanced alloys to the realm of research rather than production. The very properties that make

The global manufacturing landscape is on the cusp of a monumental transformation, with the smart factory market projected to surge from its 2025 valuation of nearly $142 billion to an astounding $265.42 billion by 2031. This rapid expansion, representing a compound annual growth rate of 10.99%, is

The immense and ever-expanding network of connected devices, from industrial sensors to smart home gadgets, presents a silent but monumental challenge of orchestration, security, and maintenance. As this digital web grows exponentially, the underlying infrastructure required to manage it is quietly

In a move designed to address critical vulnerabilities in the nation's supply chain, Indiana-based Precision Additive has officially launched the PA-300, a revolutionary metal 3D printer that promises to redefine the landscape of domestic production. This system is not merely an incremental

The operational heart of the modern factory floor is no longer just the machinery itself, but the sophisticated digital interfaces that control and interpret every process in real time. This critical nexus of human and machine interaction is driving an unprecedented expansion in the industrial