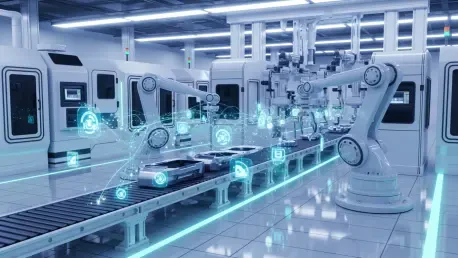

The hum of a modern industrial facility is a symphony of precision, where automated systems and intelligent robots execute tasks with seamless coordination, yet this entire operation hinges on an invisible and increasingly fragile foundation. As industries aggressively integrate automation and

The relentless pressure for perfect production runs has pushed traditional manufacturing models to their breaking point, where even the smallest deviation can trigger a cascade of costly downtime and quality failures. In response to this challenge, a new operational paradigm is emerging, one that

Serial device servers, a technology designed to connect legacy equipment with serial ports to modern Ethernet networks, are experiencing a surprising and robust resurgence that challenges the notion that newer is always better. Far from being relegated to the history books, this market is proving

Vietnam's manufacturing sector, a cornerstone of its economic ascent, now stands at a critical inflection point where its traditional advantages are being challenged by the relentless pace of global innovation and shifting market dynamics. The nation's factories, long powered by a diligent

Kwame Zaire is a leading voice in manufacturing, with a career built at the intersection of production management, industrial electronics, and operational technology security. He has a unique vantage point on the factory floor, where the digital and physical worlds collide. As industrial

A fundamental transformation is underway across the global infrastructure landscape, driven by a confluence of unprecedented challenges that have rendered traditional operational models obsolete. Faced with the pressures of climate stress, exponential demand growth from new sources like data