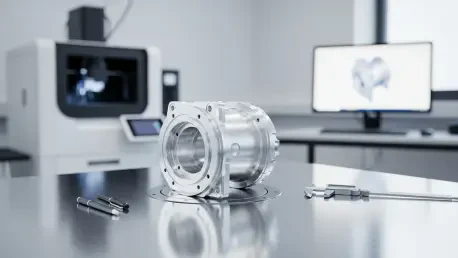

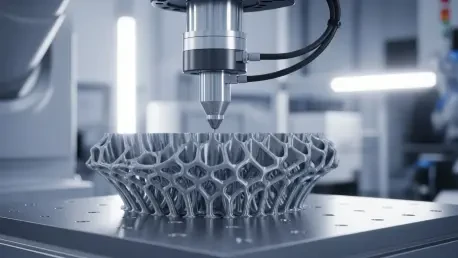

In a move designed to address critical vulnerabilities in the nation's supply chain, Indiana-based Precision Additive has officially launched the PA-300, a revolutionary metal 3D printer that promises to redefine the landscape of domestic production. This system is not merely an incremental

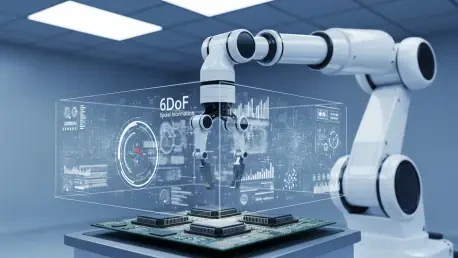

The factory floors of modern industry are undergoing a quiet yet profound transformation, moving away from the loud, repetitive clatter of rigidly programmed machinery toward a more fluid and intelligent orchestration of automated tasks. Industrial robots, long the workhorses of manufacturing, are

A groundbreaking development at the intersection of material science and artificial intelligence has unveiled a powerful new methodology for designing and analyzing complex materials, promising to overcome one of the most significant hurdles in modern engineering. Recent research illuminates how

The development of RNA-based medicines has surged forward with incredible promise, yet the journey from a digital sequence on a computer screen to a viable therapeutic in the clinic remains fraught with complex challenges and time-consuming bottlenecks. A critical disconnect has persisted between

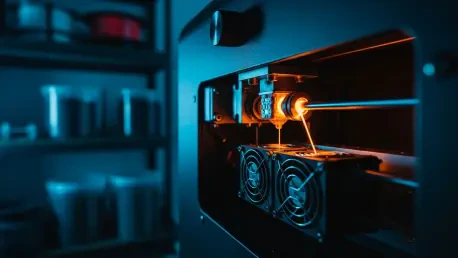

The proliferation of desktop 3D printing has brought incredible creative power to hobbyists and professionals alike, but it has also generated a growing mountain of plastic waste from failed prints, support structures, and discarded prototypes. For years, the community has dreamed of a

When a mission-critical component produced through additive manufacturing experiences an unexpected anomaly millions of miles from Earth, the search for answers begins not in a workshop, but within a labyrinth of digital records. The integrity of that data trail determines whether a failure becomes